In the highly precise and demanding world of semiconductor manufacturing, every component plays a critical role in ensuring the integrity and quality of the final product. Among these, the wafer carrier box stands out as a fundamental element for protecting and transporting delicate silicon wafers. This article delves into the importance of wafer carrier boxes, covering various aspects such as custom solutions, specific sizes like the wafer box for 200mm wafers, tips on how to buy wafer carrier box online, and the significance of wafer box cleaning service. By understanding these facets, professionals in the industry can make informed decisions to optimize their operations and maintain high standards of cleanliness and efficiency.

What is a Wafer Carrier Box?

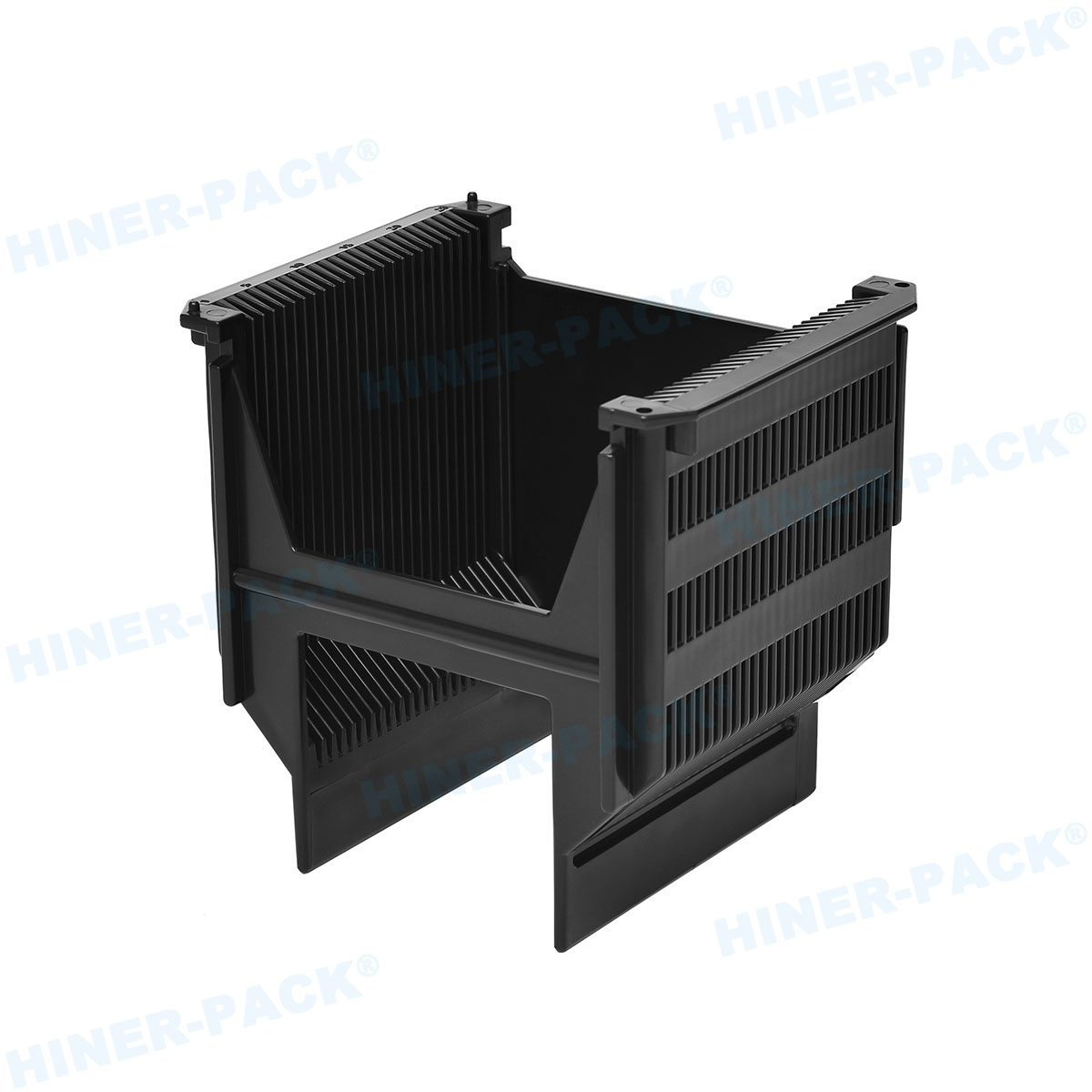

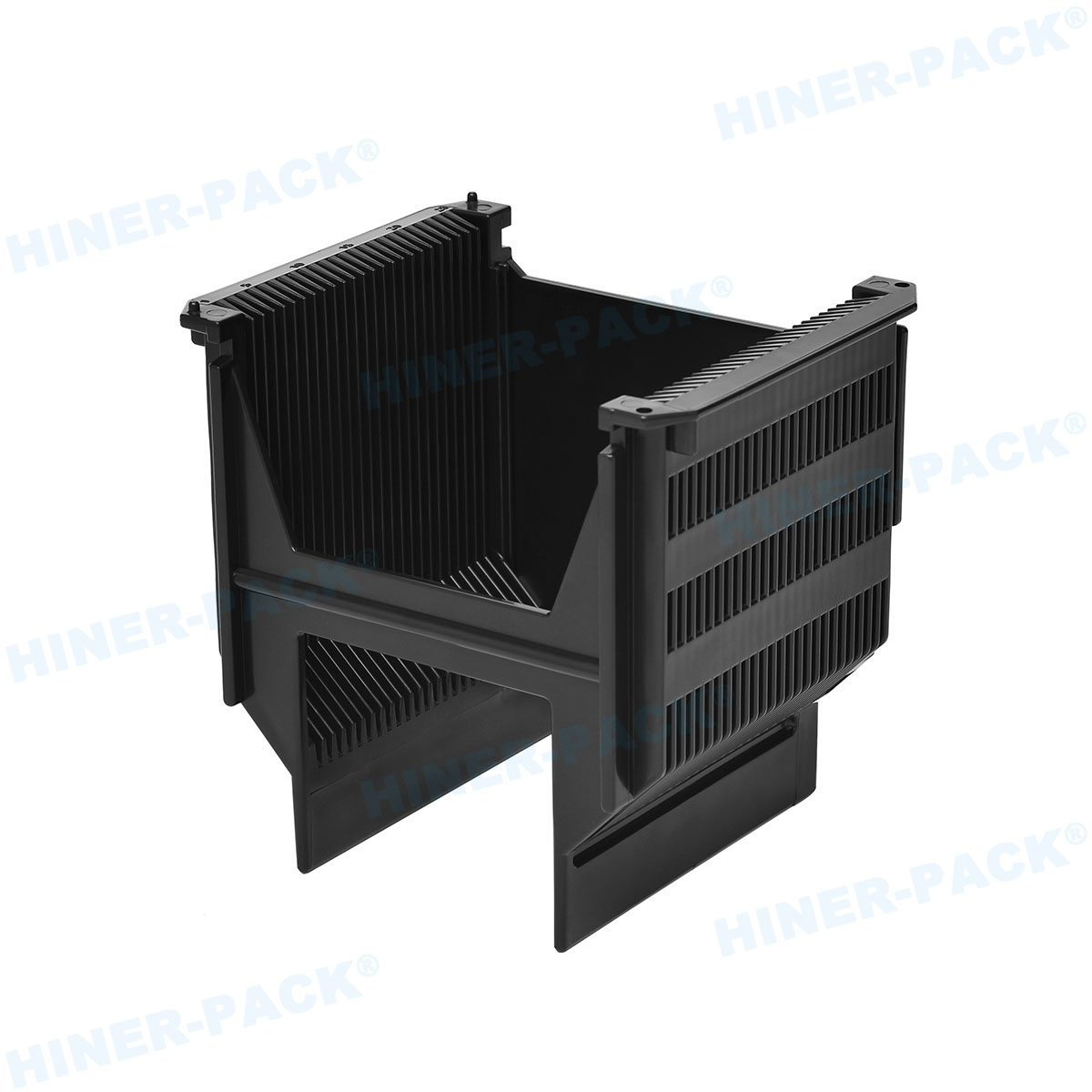

A wafer carrier box, also known as a wafer cassette or FOUP (Front Opening Unified Pod), is a specialized container designed to hold and protect silicon wafers during storage, transport, and processing in semiconductor fabrication facilities. These boxes are crafted from materials like polycarbonate or other high-purity plastics to minimize contamination and static discharge. The primary function of a wafer carrier box is to shield wafers from environmental hazards such as dust, moisture, and physical damage, which could compromise the intricate circuits etched onto their surfaces. Given the sensitivity of wafers—often worth thousands of dollars each—the reliability of a wafer carrier box is paramount. In modern cleanrooms, these boxes are integral to automated handling systems, ensuring seamless transitions between processing steps without human intervention. As semiconductor technology advances, with wafers becoming thinner and more fragile, the role of the wafer carrier box has evolved to include features like RFID tracking and enhanced ergonomic designs. This makes it not just a container, but a smart component in the supply chain.

The Advantages of a Custom Wafer Carrier Box

While standard wafer carrier box options are widely available, many companies are turning to custom wafer carrier box solutions to meet unique operational needs. A custom wafer carrier box can be tailored to specific wafer sizes, materials, or environmental conditions, offering enhanced protection and efficiency. For instance, in facilities dealing with extreme temperatures or corrosive chemicals, a custom wafer carrier box might be made from advanced composites that resist degradation. Additionally, customization allows for integration with existing automation systems, reducing downtime and improving workflow. Companies investing in a custom wafer carrier box often see long-term cost savings due to reduced breakage and contamination-related losses. Moreover, a custom wafer carrier box can include proprietary features like specialized locking mechanisms or anti-static coatings, which are crucial for high-yield production lines. When considering a custom wafer carrier box, it's essential to collaborate with manufacturers who understand industry standards such as SEMI guidelines to ensure compatibility and safety. This level of personalization not only boosts performance but also provides a competitive edge in the fast-paced semiconductor market.

Focusing on the Wafer Box for 200mm Wafers

The wafer box for 200mm wafers remains a staple in many semiconductor operations, particularly in fabs that handle legacy technologies or specific applications. Despite the industry's shift toward larger 300mm wafers, the wafer box for 200mm wafers is still in high demand due to its cost-effectiveness and versatility in producing a wide range of devices, from microcontrollers to sensors. A typical wafer box for 200mm wafers is designed to hold 25 wafers, with precise slot spacing to prevent contact and scratching. These boxes often feature robust construction to withstand repeated use in harsh environments, and they must comply with SEMI standards for dimensions and materials. When selecting a wafer box for 200mm wafers, factors like static dissipation, chemical resistance, and ease of handling come into play. For companies looking to buy wafer carrier box online, it's crucial to verify that the wafer box for 200mm wafers meets all regulatory requirements to avoid compatibility issues. Furthermore, as part of a comprehensive maintenance strategy, a wafer box cleaning service can extend the life of these containers, ensuring they remain free from particulate contamination that could ruin expensive wafers.

How to Buy Wafer Carrier Box Online

In today's digital age, the ability to buy wafer carrier box online has revolutionized procurement for semiconductor companies. Online platforms offer a wide selection of wafer carrier box options, from standard models to custom wafer carrier box designs, making it easier to compare prices and specifications. When you buy wafer carrier box online, you can access detailed product information, customer reviews, and technical datasheets, which aid in making informed decisions. Key considerations include material quality, compliance with industry standards, and supplier reputation. For instance, if you need a wafer box for 200mm wafers, filter your search to ensure compatibility. Many online suppliers also offer bulk discounts and fast shipping, which is essential for minimizing production delays. However, it's important to be cautious—verify the supplier's credentials and look for certifications like ISO 9001 to guarantee product reliability. Additionally, some online stores provide value-added services such as a wafer box cleaning service, which can be bundled with purchases for added convenience. By leveraging online resources, companies can streamline their supply chain and reduce costs while maintaining high standards for their wafer carrier box needs.

The Importance of Wafer Box Cleaning Service

A wafer box cleaning service is a critical aspect of semiconductor maintenance that ensures the longevity and performance of wafer carrier box units. Over time, these boxes can accumulate contaminants like dust, residues, and microbes, which pose a significant risk to wafer integrity. Regular cleaning through a professional wafer box cleaning service helps prevent defects and yield losses in fabrication processes. This service typically involves ultrasonic cleaning, deionized water rinsing, and drying in controlled environments to achieve the required cleanliness levels, often specified by SEMI standards. Companies that utilize a wafer box cleaning service can schedule routine maintenance to avoid unexpected downtime, and many providers offer on-site or off-site options based on volume and urgency. For those who buy wafer carrier box online, it's wise to inquire about cleaning packages, as a well-maintained wafer carrier box can last years longer than neglected ones. Moreover, a wafer box cleaning service is especially vital for custom wafer carrier box designs, which may have intricate features that require specialized cleaning techniques. By integrating this service into their operations, semiconductor firms can uphold strict contamination control protocols and protect their investments.

Key Factors in Selecting the Right Wafer Carrier Box

Choosing the appropriate wafer carrier box involves evaluating several factors to ensure it aligns with your operational requirements. First, consider the wafer size—whether you need a standard wafer box for 200mm wafers or a larger variant. Material composition is another critical aspect; look for boxes made from high-purity, static-dissipative plastics to minimize contamination risks. If your processes demand unique features, opting for a custom wafer carrier box might be necessary. Ease of integration with automated systems is also important, as it affects efficiency in high-volume production environments. When you plan to buy wafer carrier box online, check for certifications and customer support options to address any issues promptly. Don't overlook the value of a wafer box cleaning service in maintaining box integrity over time. Cost is always a factor, but investing in a high-quality wafer carrier box can lead to savings by reducing wafer loss and downtime. Ultimately, a thorough assessment of these elements will help you select a wafer carrier box that enhances your semiconductor handling capabilities.

Future Trends in Wafer Carrier Box Technology

The evolution of the wafer carrier box is closely tied to advancements in semiconductor technology. As wafers become larger and more complex, wafer carrier box designs are adapting to include smart features like IoT connectivity for real-time tracking and environmental monitoring. For example, a custom wafer carrier box might incorporate sensors that detect temperature, humidity, or shock, providing data to prevent damage during transit. Sustainability is another growing trend, with manufacturers developing recyclable materials for wafer carrier box production to reduce environmental impact. The wafer box for 200mm wafers is also seeing updates, such as lightweight designs that improve handling efficiency. Online platforms for purchasing are becoming more sophisticated, offering virtual simulations to help customers buy wafer carrier box online with confidence. Additionally, the wafer box cleaning service industry is embracing automation, using robotics to achieve higher precision and faster turnaround times. These innovations ensure that the wafer carrier box remains a vital component in the semiconductor ecosystem, driving efficiency and reliability in an ever-changing landscape.

In summary, the wafer carrier box is an indispensable tool in the semiconductor industry, offering protection and efficiency for valuable wafers. From the versatility of a custom wafer carrier box to the specific requirements of a wafer box for 200mm wafers, understanding these options is key to optimizing operations. The convenience to buy wafer carrier box online has made procurement more accessible, while the availability of a wafer box cleaning service ensures long-term reliability. By staying informed about these aspects, companies can make strategic choices that enhance productivity and safeguard their investments. As technology progresses, the wafer carrier box will continue to evolve, incorporating new features to meet the demands of next-generation semiconductor manufacturing.

Frequently Asked Questions (FAQ)

Q1: What is the primary purpose of a wafer carrier box?

A1: The primary purpose of a wafer carrier box is to protect silicon wafers from contamination, physical damage, and environmental factors during storage, transport, and processing in semiconductor facilities. It ensures the wafers remain clean and intact, which is crucial for maintaining high yields in production.

Q2: How does a custom wafer carrier box differ from standard ones?

A2: A custom wafer carrier box is tailored to specific operational needs, such as unique wafer sizes, material requirements, or integration with automated systems. Unlike standard boxes, it may include specialized features like enhanced static protection or custom dimensions, offering better performance and cost-efficiency for particular applications.

Q3: Why is the wafer box for 200mm wafers still relevant today?

A3: The wafer box for 200mm wafers remains relevant because many semiconductor fabs still use 200mm wafers for producing a variety of devices, including analog chips and sensors. Its cost-effectiveness and compatibility with existing equipment make it a practical choice for certain manufacturing processes.

Q4: What should I consider when I buy wafer carrier box online?

A4: When you buy wafer carrier box online, consider factors such as material quality, compliance with industry standards (e.g., SEMI), supplier reputation, and customer reviews. Also, check for options like a wafer box cleaning service and ensure the product meets your specific size and customization needs.

Q5: How often should I use a wafer box cleaning service?

A5: The frequency of using a wafer box cleaning service depends on your operational environment and usage intensity. Generally, it's recommended to clean wafer carrier box units every few months or after each major production run to prevent contamination buildup. Regular maintenance schedules can be established based on risk assessments and historical data.