In semiconductor manufacturing, the safe and efficient movement of silicon wafers is fundamental. A critical, yet sometimes overlooked, specification is the wafer carrier load capacity. This term refers to the maximum number of wafers a carrier can safely hold and transport without risking damage, contamination, or misalignment. This article will explain wafer carrier load capacity, its impact on production, and how Hiner-pack engineers carriers to meet precise capacity demands.

What is Wafer Carrier Load Capacity?

Wafer carrier load capacity defines the operational limits of a carrier. It is not just about the physical count of wafers. The capacity encompasses the total weight, the mechanical stress on the carrier structure, and the safe handling during robotic transfer.

Key elements include:

Maximum Wafer Count: The number of slots (e.g., 25 for 300mm wafers).

Static Load: Weight supported when the carrier is stationary.

Dynamic Load: Weight supported during movement, transfer, or vibration.

Thermal Load: Performance under high-temperature processes without deformation.

Understanding wafer carrier load capacity is essential for selecting the right tool for each process step.

Why Load Capacity Matters in Fab Operations

Ignoring load specifications can lead to significant problems. A carrier operating beyond its designed limits poses risks to both product and equipment.

Consequences of exceeding capacity include:

Wafer breakage or micro-cracks from excessive stress.

Increased particle generation due to wafer friction or carrier deformation.

Misalignment in tool ports, causing automation errors and downtime.

Premature wear and failure of the carrier itself.

Adhering to the specified wafer carrier load capacity ensures process stability, protects capital investment, and safeguards yield.

Factors Influencing Wafer Carrier Load Capacity

Several design and material factors determine how much load a carrier can handle. Manufacturers like Hiner-pack balance these elements for optimal performance.

Carrier Material and Construction

The base material is the primary factor. Common materials have different strength-to-weight ratios.

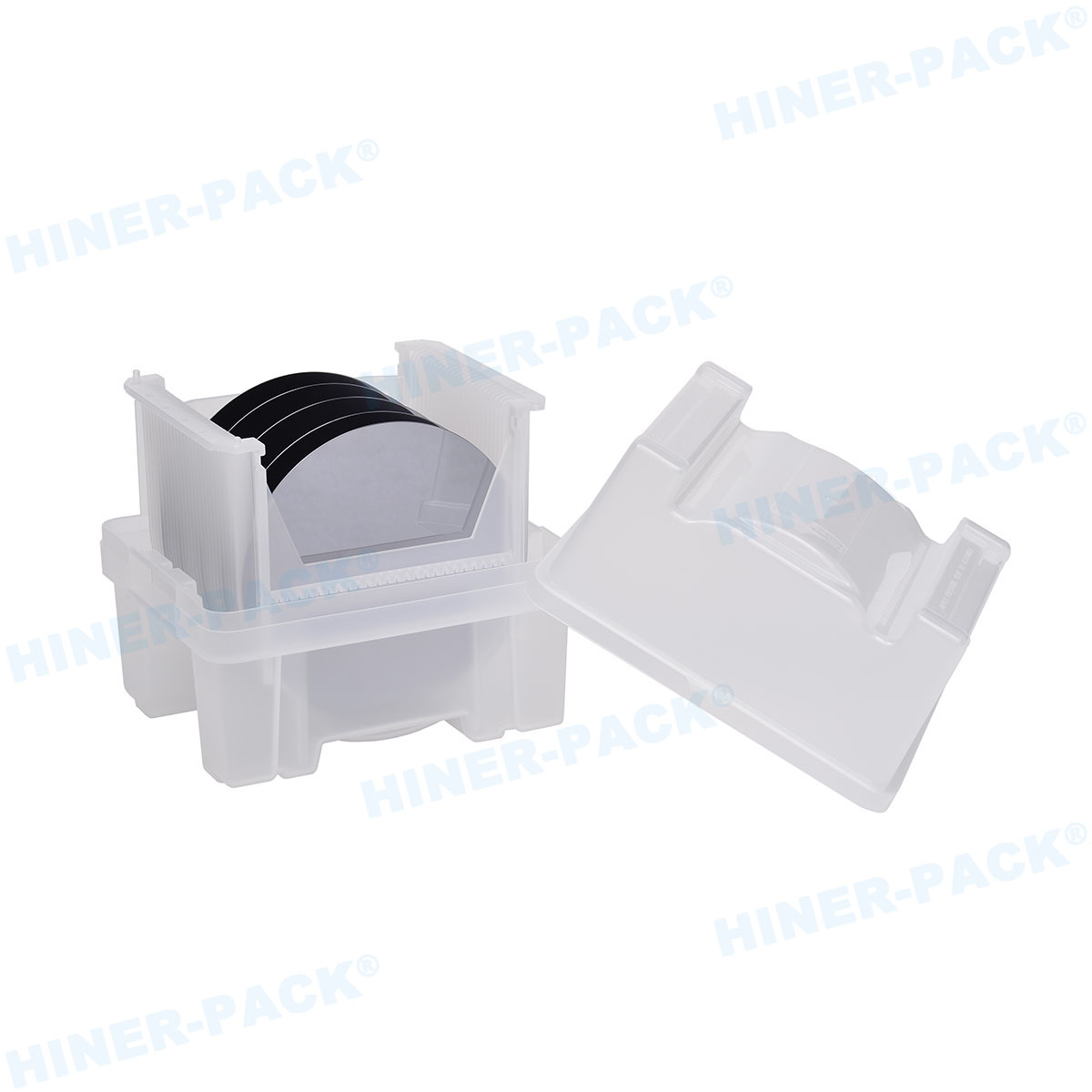

PP/PFA Plastics: Used for standard FOUPs and FOSBs. Load capacity is designed for a full set of wafers under cleanroom conditions.

Advanced Composites: Offer higher strength for minimal added weight, supporting larger wafer counts.

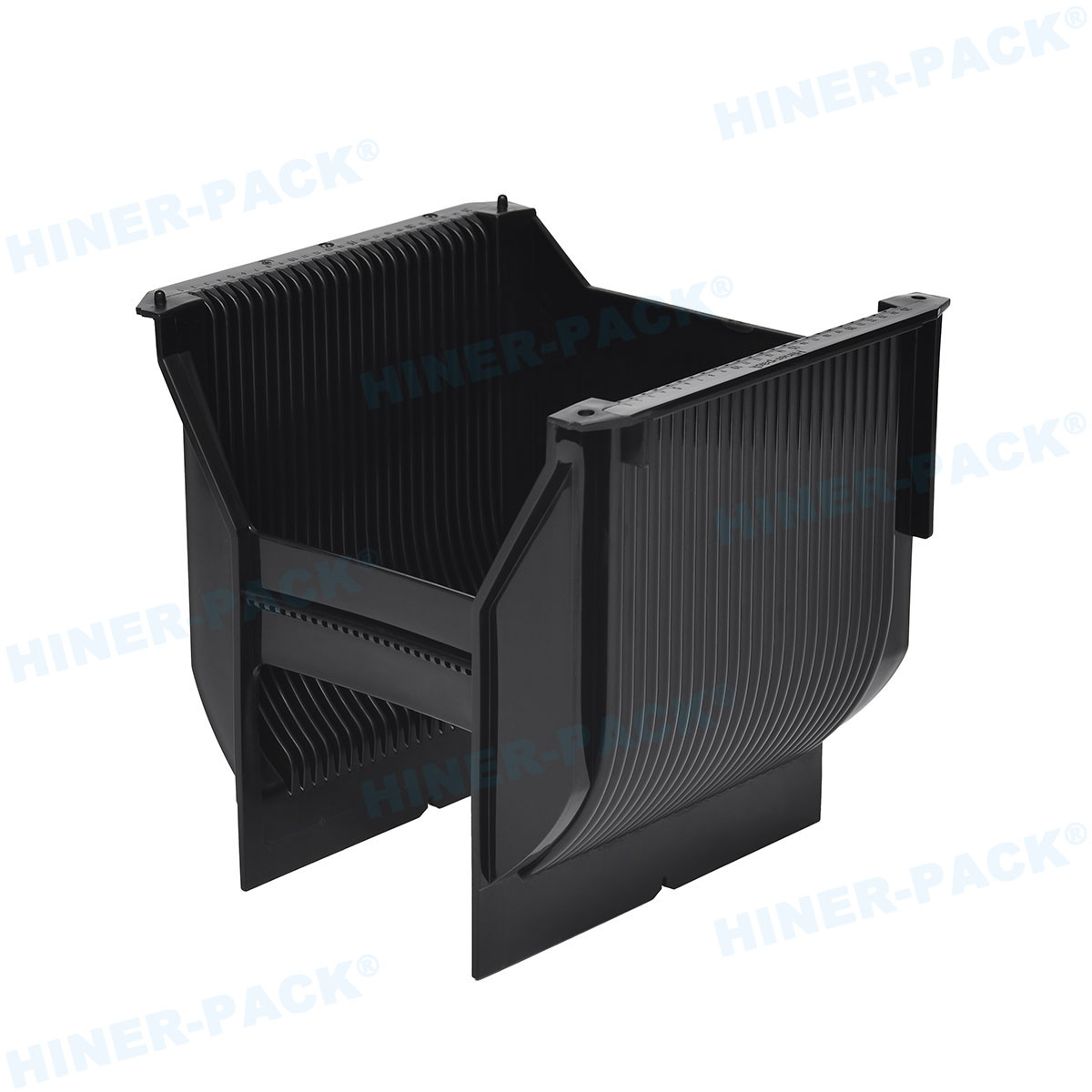

Quartz & Silicon Carbide: Used in high-temperature boats. Their capacity must account for high thermal stress in addition to physical weight.

Structural Design and Reinforcement

Engineering design directly impacts capacity. Key features include:

Ribbed structures for added rigidity without extra mass.

Precision-molded wafer slots that distribute weight evenly.

Reinforcement at critical stress points, such as handling grooves and robotic flange areas.

Hiner-pack uses finite element analysis to simulate stress points. This optimizes the design for the intended wafer carrier load capacity.

Wafer Size and Thickness Trends

The shift to larger, thinner wafers changes load dynamics. A 300mm wafer is heavier and more fragile than a 200mm wafer. Future 450mm wafers will demand carriers with significantly higher structural integrity.

Carrier designs must evolve to manage the increased weight and bending moments while protecting delicate wafers.

Measuring and Testing Load Capacity

Reliable carriers undergo rigorous testing. This verifies their rated capacity under real-world conditions.

Standard tests include:

Static Load Testing: Applying a constant weight to the carrier for an extended period.

Dynamic Fatigue Testing: Simulating thousands of robotic transfers and vibrations.

Thermal Cycle Testing: Exposing loaded carriers to process temperature cycles to check for warping.

Drop and Impact Testing: Ensuring the carrier can withstand minor handling incidents.

Hiner-pack conducts these tests to certify the safe wafer carrier load capacity of every product line.

Optimizing Load Capacity for Process Efficiency

Finding the right balance is key. Maximizing wafer count per carrier improves throughput but must not compromise safety.

Optimization strategies:

Process-Specific Carriers: Using different carriers for diffusion (high-temp) versus metrology (room-temp) steps.

Automation Compatibility: Ensuring the loaded carrier weight is within the robot's payload specification.

Regular Maintenance Checks: Inspecting carriers for cracks or wear that degrade their load capacity over time.

A well-planned approach to wafer carrier load capacity contributes directly to overall equipment effectiveness (OEE).

Hiner-pack's Approach to Engineered Load Capacity

Hiner-pack designs carriers with a clear focus on reliable, specified load capacity. We understand that our products are a critical link in the manufacturing chain.

Our engineering principles:

Material Science: Selecting and compounding resins for optimal strength and cleanliness.

Precision Manufacturing: Consistent molding processes to eliminate weak points.

Transparent Specifications: Providing clear data sheets with certified static and dynamic load limits.

Custom Solutions: Working with customers to design carriers for unique weight or size requirements.

By prioritizing a robust wafer carrier load capacity, Hiner-pack helps fabs minimize risk and maintain continuous production flow

Wafer carrier load capacity is a fundamental specification that intersects with yield, equipment safety, and productivity. It requires careful consideration of materials, design, and real-world process conditions. As wafers increase in size and value, the role of the carrier becomes more critical. Partnering with experienced manufacturers like Hiner-pack ensures that your operations are built on a foundation of reliable, high-capacity wafer handling solutions.

Frequently Asked Questions (FAQs)

Q1: How is wafer carrier load capacity different from just the number of slots?

A1: The number of slots indicates maximum wafer count. Load capacity is a broader engineering specification that includes the total weight of wafers, the carrier's ability to handle that weight during movement (dynamic load), and its performance under environmental stress like heat.

Q2: What happens if I accidentally exceed the carrier's load capacity?

A2: Exceeding capacity can cause immediate or gradual failure. Risks include wafer breakage, increased particles, carrier cracking, and misalignment in automated tools. This can lead to scrap, tool downtime, and costly carrier replacement.

Q3: Does the wafer thickness affect the load capacity of a carrier?

A3: Yes. Thicker wafers are heavier. A carrier loaded with thick test wafers may reach its weight limit before all slots are filled. Always consider the weight per wafer, not just the count, relative to the carrier's rated capacity.

Q4: How does Hiner-pack test and certify the load capacity of its carriers?

A4: Hiner-pack employs rigorous mechanical testing, including static load compression, dynamic fatigue cycles, and thermal stability tests. We certify our carriers to meet or exceed SEMI standards and provide clear load ratings for safe operation.

Q5: For high-temperature processes, does the load capacity change?

A5: Yes. Materials like quartz can soften at high temperatures. The effective load capacity at 1000°C is often lower than at room temperature. It is vital to consult the manufacturer's specifications for the rated thermal load capacity for high-temperature applications.