In the fast-paced world of semiconductor manufacturing, every component must ensure precision and safety. Among these, wafer cassette racks play a critical role. They provide organized storage and transport for silicon wafers housed in cassettes, preventing damage and contamination. This simple yet vital equipment supports seamless fab operations. Companies like Hiner-pack specialize in designing robust racks that meet industry standards. As fabs scale up, the demand for durable wafer cassette racks grows. This article delves into their function, types, and selection criteria.

What Are Wafer Cassette Racks?

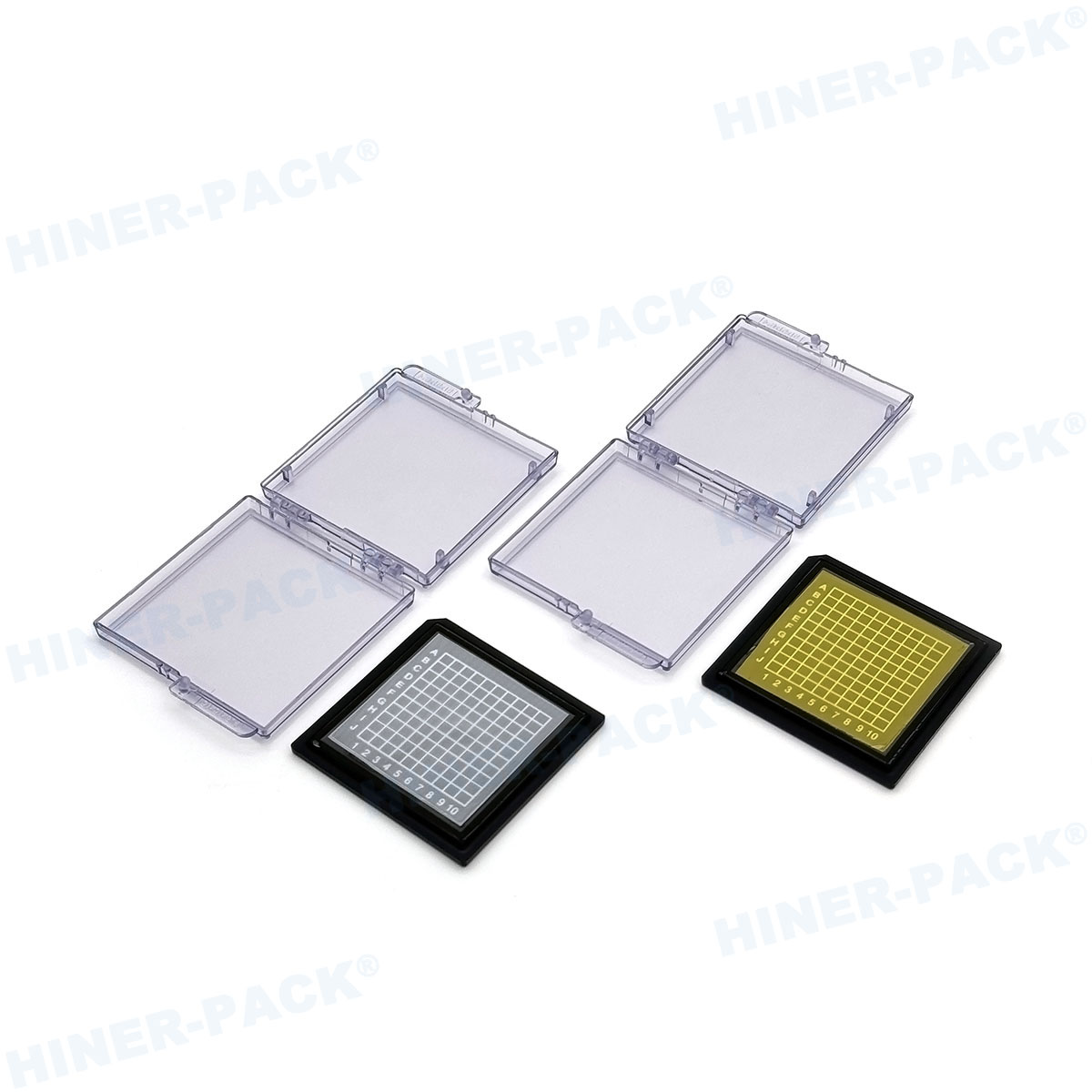

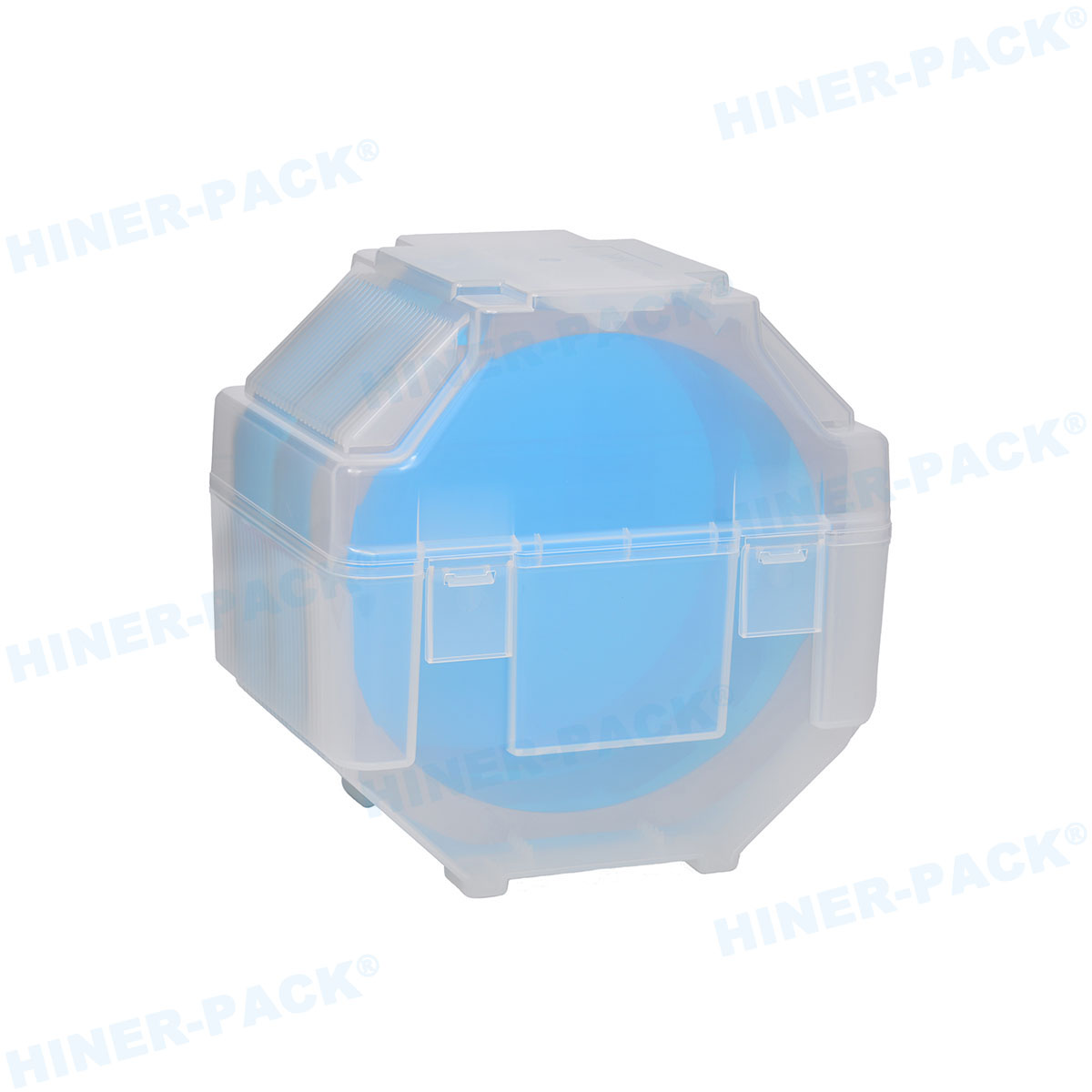

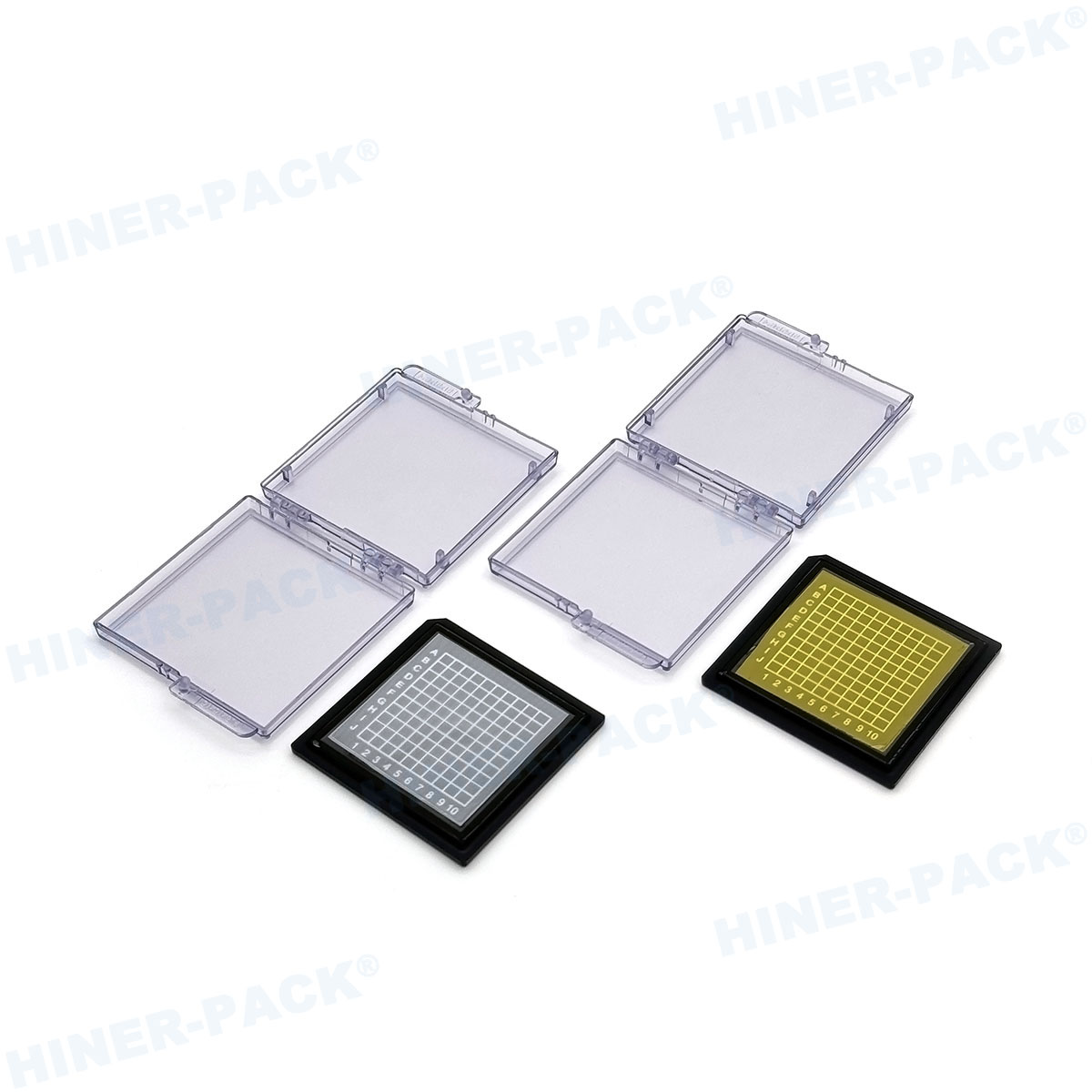

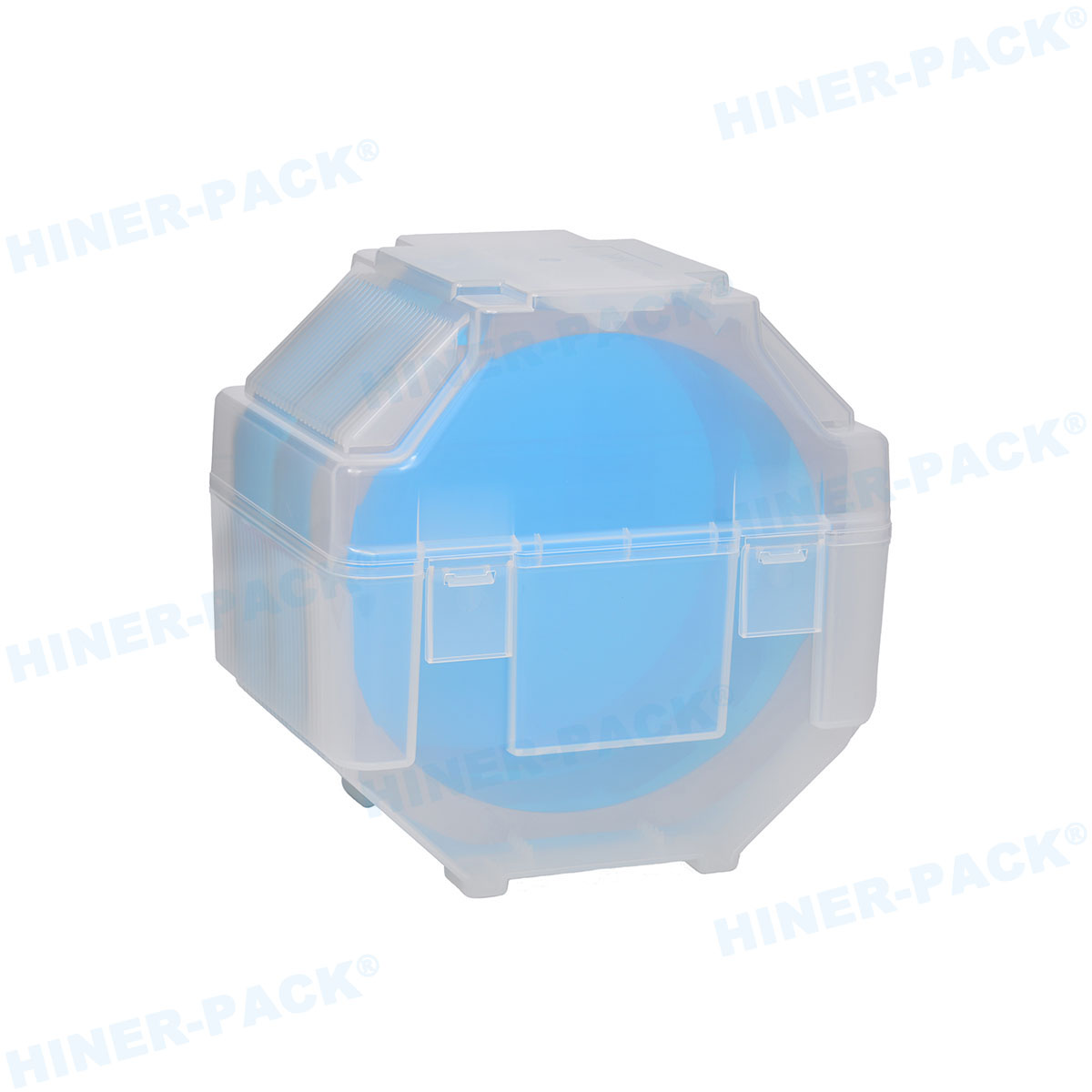

Wafer cassette racks are structural frames used to hold multiple wafer cassettes securely. They are common in cleanrooms and storage areas. These racks keep wafers organized during processing or transit. Typically made from materials like stainless steel or plastics, they resist corrosion and particles. Standard designs accommodate various cassette sizes, such as 200mm or 300mm wafers. Proper use minimizes handling errors and boosts efficiency. For many technicians, wafer cassette racks are everyday essentials.

Key Functions in Semiconductor Fabs

The primary job of these racks is to safeguard wafers. They prevent cassettes from tipping over, reducing breakage risks. In high-volume fabs, racks enable systematic workflow. Workers can quickly access wafers for lithography or etching steps. Storage racks also save floor space in crowded cleanrooms. By reducing clutter, they help maintain cleanliness standards. Contamination control is vital, and well-designed racks limit particle generation. Thus, wafer cassette racks contribute directly to yield improvement.

Types of Wafer Cassette Racks

Different applications require specific rack designs. Static racks are fixed units for long-term storage. They often feature multiple shelves or slots. Mobile racks come with wheels for easy movement between tools. These are useful in dynamic production lines. Another type is the transport rack, used for shipping wafers between facilities. These have locking mechanisms for safety. Custom racks are also available for unique cassette configurations. Hiner-pack offers a range of types to suit diverse needs.

Materials and Construction Details

Material choice impacts performance. Stainless steel is popular for its strength and cleanability. It withstands frequent cleaning with chemicals. Plastic racks, like those made from PEEK, are lightweight and static-dissipative. They are ideal for sensitive environments. Construction features include rounded edges to prevent wafer scratches. Some racks have anti-vibration properties for delicate processes. Hiner-pack uses advanced manufacturing to ensure precise tolerances. This attention to detail extends rack lifespan.

Integration with Automated Systems

Modern fabs rely on automation. Wafer cassette racks must interface with robots and conveyors. Standardized dimensions allow smooth handoff to equipment. Racks with barcode labels enable tracking via MES software. Automated storage and retrieval systems use racks for buffer storage. Compatibility reduces downtime during material handling. Hiner-pack designs racks that align with industry automation protocols. This integration streamlines the entire wafer journey.

Hiner-pack's Approach to Rack Solutions

Hiner-pack focuses on innovation in wafer handling storage. Their racks are tested for durability in harsh conditions. The company offers customization based on client specifications. For instance, racks can be designed for high-temperature environments. Hiner-pack also provides consulting on rack layout for optimal space use. Their products comply with SEMI standards, ensuring global acceptance. By prioritizing quality, Hiner-pack helps fabs minimize operational hiccups.

Selecting the Right Rack for Your Fab

Choosing racks involves several factors. Consider wafer size and cassette type first. Assess the storage capacity needed per rack. Evaluate material compatibility with cleanroom chemicals. Check for certifications like SEMI S2 for safety. Budget constraints may influence decisions, but long-term reliability matters more. Hiner-pack’s team can guide selections based on production volume. A good fit enhances overall equipment effectiveness.

Maintenance and Cleaning Protocols

Regular upkeep extends rack life. Clean racks periodically with approved solvents. Inspect for wear, especially on loading surfaces. Replace damaged racks promptly to avoid wafer loss. Hiner-pack provides maintenance guidelines with their products. Proper handling during cleaning prevents contamination. Documenting maintenance schedules helps in audits. These steps ensure wafer cassette racks remain functional for years.

Industry Trends Impacting Rack Design

As wafers grow larger, racks must adapt. 450mm wafer adoption may drive new rack designs. Sustainability trends push for recyclable materials. Smart racks with embedded sensors are emerging. These monitor temperature or humidity in real-time. Hiner-pack invests in R&D to stay ahead of trends. Future racks may integrate more with IoT systems. Staying updated ensures fabs remain competitive.

Safety and Ergonomics Considerations

Worker safety is paramount. Racks should be stable to prevent tipping injuries. Ergonomic designs reduce strain during loading. Labels and color-coding enhance visual management. Hiner-pack incorporates safety features like locking casters on mobile racks. Training staff on proper rack use minimizes accidents. A safe workspace improves productivity and morale.

Cost-Benefit Analysis of Quality Racks

Investing in high-quality wafer cassette racks pays off. They reduce wafer loss due to damage. Efficient storage cuts downtime in material retrieval. Durable racks lower replacement frequency. Hiner-pack’s solutions offer a strong return on investment. Consider total cost of ownership, not just upfront price. Reliable racks support continuous production flow.

Wafer Cassette Racks in Global Supply Chains

These racks are crucial for logistics. They protect wafers during international shipping. Standardized racks simplify cross-fab transfers. Hiner-pack serves clients worldwide, ensuring consistent quality. Supply chain resilience depends on robust handling equipment. As fabs expand globally, rack reliability becomes even more critical.

Final Thoughts on Wafer Cassette Racks

Wafer cassette racks are unsung heroes in semiconductor manufacturing. They provide the foundation for organized wafer management. From storage to transport, their role is indispensable. Selecting the right racks, like those from Hiner-pack, can optimize fab performance. As technology evolves, these racks will continue to adapt. Embracing best practices ensures they remain a valuable asset.

Frequently Asked Questions

Q1: What are the standard sizes for wafer cassette racks?

A1: Standard racks typically accommodate cassettes for 150mm, 200mm, or 300mm wafers. Sizes vary based on SEMI guidelines. Hiner-pack offers racks for these common dimensions, with customization available for special needs.

Q2: How do I clean wafer cassette racks properly?

A2: Use cleanroom-compatible solvents and lint-free wipes. Follow manufacturer instructions, such as those from Hiner-pack, to avoid material degradation. Regular cleaning prevents particle buildup and contamination.

Q3: Can wafer cassette racks be used in automated systems?

A3: Yes, many racks are designed for automation. They feature standardized interfaces for robots and conveyors. Hiner-pack provides racks compatible with popular automated material handling systems.

Q4: What materials are best for corrosive environments?

A4: Stainless steel with high corrosion resistance is ideal. Plastics like PVDF also perform well. Hiner-pack can recommend materials based on specific chemical exposures in your fab.

Q5: How long do wafer cassette racks typically last?

A5: With proper maintenance, quality racks can last 5-10 years or more. Factors like usage frequency and environment affect lifespan. Hiner-pack’s racks are built for durability to ensure long-term service.