In the highly precise world of semiconductor manufacturing, every component matters. The safe transportation and storage of delicate silicon wafers is not a logistical afterthought; it is a critical requirement. This is where the role of a specialized wafer shipper manufacturer becomes paramount.

Selecting the right manufacturing partner is a decision that directly impacts yield, contamination control, and overall operational cost.

The Critical Role of Wafer Shippers in the Fab Ecosystem

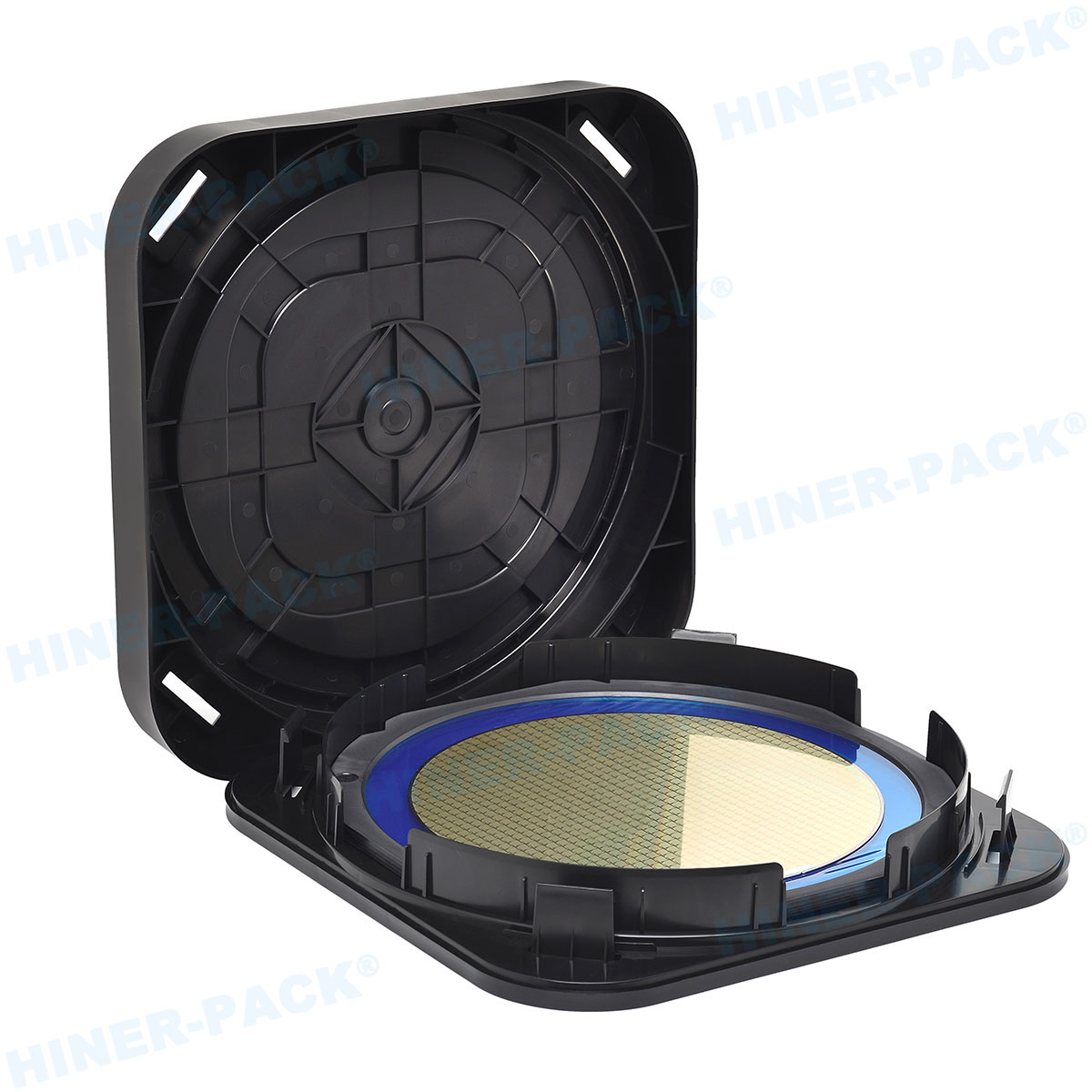

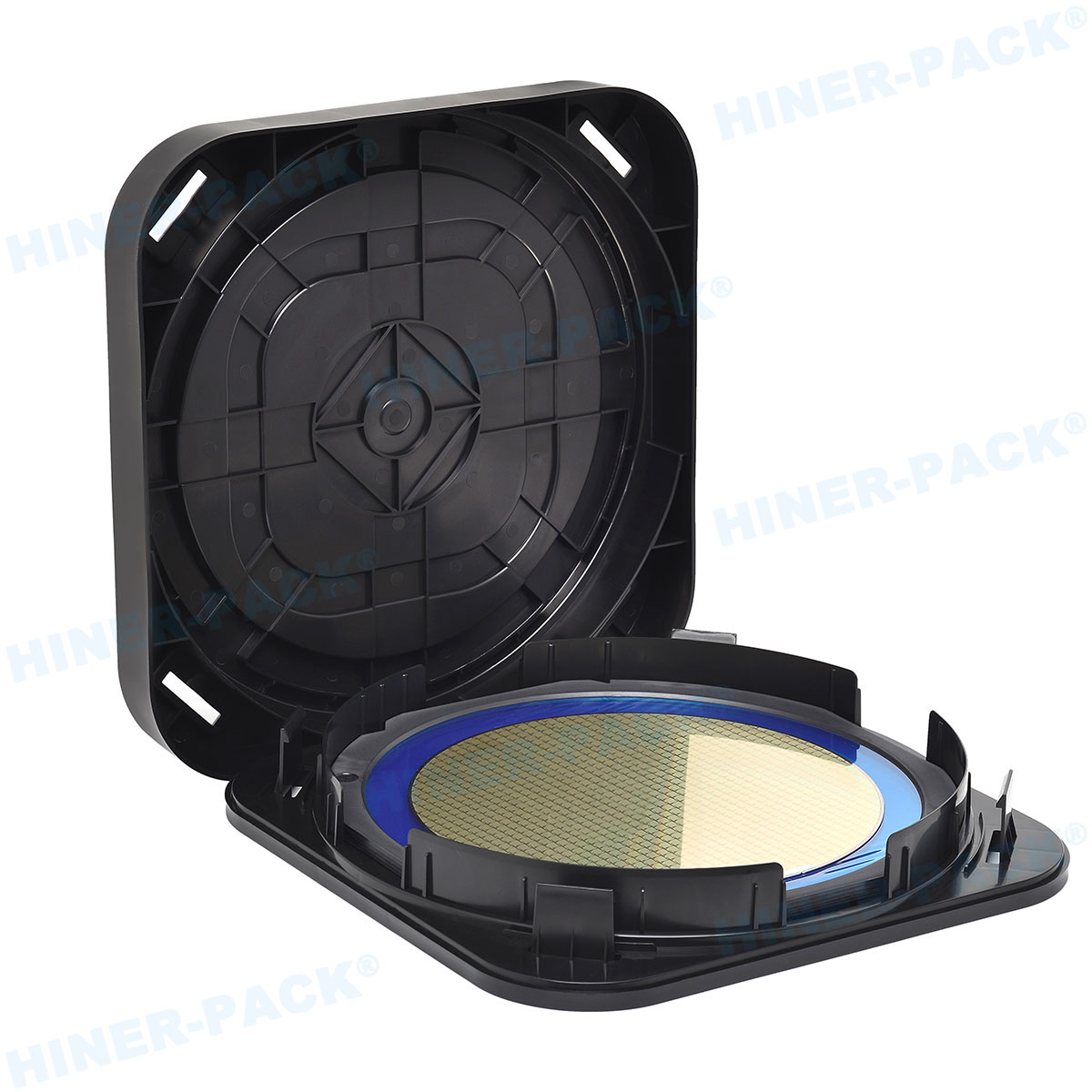

Wafer shippers, also known as wafer carriers or FOUP/FOSB compatibles, are the frontline guardians of wafer integrity. They protect wafers from physical damage, electrostatic discharge (ESD), and most critically, airborne molecular contamination (AMC) and particles.

A reliable wafer shipper manufacturer understands the entire fab environment. Their products must integrate seamlessly with automated material handling systems (AMHS), stockers, and processing tools.

Failure at this stage can lead to catastrophic yield loss. Therefore, the manufacturer's expertise is as vital as the toolmaker's.

Key Selection Criteria for a Wafer Shipper Manufacturer

Not all manufacturers are equal. When evaluating a potential partner, consider these non-negotiable factors:

Material Science Prowess: The choice of polymer, such as advanced PP or PEEK, is fundamental. It must offer low outgassing, high rigidity, and excellent cleanability. The manufacturer must have deep knowledge in polymer selection for specific process nodes.

Precision Engineering & Dimensional Stability: Carriers must meet strict SEMI standards (e.g., SEMI E62, E1.9). Tolerances are measured in microns. Inconsistent molding can cause misalignment, wafer chipping, or tool jams.

Contamination Control Commitment: The manufacturer's own production environment should be a certified cleanroom. Their processes must be designed to minimize particle generation and residual static charge.

Customization Capability: Standard designs don't always fit unique needs. A leading custom wafer shipper manufacturer like Hiner-pack offers tailored solutions. This includes custom ribs, pockets for 200mm, 300mm, or emerging sizes, RFID integration, and specialized colors for lot differentiation.

Beyond the Product: Assessing Technical Support and Service

The business relationship extends beyond the initial purchase. A true partner provides comprehensive support.

Look for a manufacturer that offers design validation services, failure analysis, and consistent quality audits. They should act as an extension of your quality assurance team.

Hiner-pack, for instance, partners with clients from the prototype phase through high-volume production. This ensures the final wafer shipper is perfectly optimized for its intended application.

Understanding Cost vs. Value in Wafer Shipper Procurement

The lowest price per unit can be misleading. Total Cost of Ownership (TCO) is the key metric.

A slightly higher initial investment in a quality carrier from a reputable manufacturer pays dividends. It reduces the risk of wafer loss, minimizes downtime due to carrier-related tool faults, and extends the carrier's usable lifecycle through effective cleaning.

Consider the cost of a single wafer scrapped due to contamination. A reliable carrier is inexpensive insurance.

Deep Dive: The Technology and Craftsmanship Behind Hiner-pack

As a dedicated wafer shipper manufacturer, Hiner-pack distinguishes itself through integrated technology and meticulous craftsmanship.

Our process begins with premium, semiconductor-grade resins. We employ state-of-the-art injection molding machines in a Class 1000 cleanroom environment. This ensures every wafer shipper is born clean.

Our engineering team focuses on structural optimization. We design for maximum stiffness with minimal material, reducing weight and potential outgassing surface area. Every mold is precision-machined and regularly maintained to guarantee dimensional fidelity, lot after lot.

Furthermore, Hiner-pack excels as a custom wafer shipper manufacturer. We collaborate on designs for specialized applications, such as carriers for ultra-thin wafers or for harsh chemical transport, modifying materials and structures accordingly.

Choosing a Partner for the Long Term

The semiconductor industry's roadmap demands continuous advancement. Your chosen wafer shipper manufacturer must be an innovator, committed to R&D for next-generation requirements, including larger wafer formats and more stringent contamination controls.

They must have a robust global supply chain and consistent quality control across all production facilities.

Selecting a wafer shipper manufacturer is a strategic decision. It requires careful evaluation of technical capability, quality systems, and the willingness to provide tailored solutions. The goal is to find a partner who views your wafer safety as their own mission.

Brands like Hiner-pack have built their reputation on this principle, offering not just a product, but a guarantee of integrity for the most valuable assets in the fab.

Frequently Asked Questions (FAQs)

Q1: What is the most critical property to look for in a wafer shipper from a manufacturer?

A1: While all properties are important, low contamination generation is paramount. This encompasses low outgassing (to prevent AMC), minimal particle shedding, and effective static dissipation. A reputable wafer shipper manufacturer will have quantifiable data from tests like TD-GCMS and particle counts to validate their performance.

Q2: Can a manufacturer customize a wafer shipper for my specific tool or wafer process?

A2: Yes, a capable custom wafer shipper manufacturer like Hiner-pack regularly modifies designs. Customizations can include unique flange designs for tool interfacing, specific pocket layouts for non-standard wafer sizes or thicknesses, integrated sensors, and bespoke mechanical features for specialized automation.

Q3: How often should wafer shippers be replaced, and what are the signs of wear?

A3: There's no fixed timeline; it depends on usage and cleaning cycles. Signs of end-of-life include visible cracks or deformations, increased particle counts after cleaning, difficulty in sealing, or failure in tool load ports. Regular inspection and monitoring programs, often supported by the manufacturer, are essential.

Q4: Are there significant differences between manufacturers for different wafer sizes (e.g., 200mm vs. 300mm)?

A4: The core competencies of material science and precision molding apply to all sizes. However, the engineering challenges differ. 300mm and larger carriers are heavier and subject to greater mechanical stress, requiring superior structural design. An experienced manufacturer will have proven expertise across the full range of sizes your fab utilizes.

Q5: What should I expect from a manufacturer in terms of quality documentation and traceability?

A5: You should expect full lot traceability back to the raw material batch. Comprehensive documentation, including Material Data Sheets, Certificate of Analysis (CoA), cleanroom production certificates, and compliance statements with relevant SEMI standards, is standard practice from a professional wafer shipper manufacturer. This is crucial for your quality management and audit trails.