In the highly precise world of semiconductor manufacturing, every component plays a critical role in ensuring efficiency, safety, and yield. One such component that often goes unnoticed but is vital for handling delicate wafers is the 4 inch wafer carrier. If you're involved in electronics production, research, or any field requiring wafer-based technologies, understanding the 4 inch wafer carrier can significantly impact your operations. This article delves into the key aspects of the 4 inch wafer carrier, explaining its importance, design, applications, and more. By the end, you'll see why this tool is indispensable in cleanrooms and laboratories worldwide.

What Is a 4 Inch Wafer Carrier?

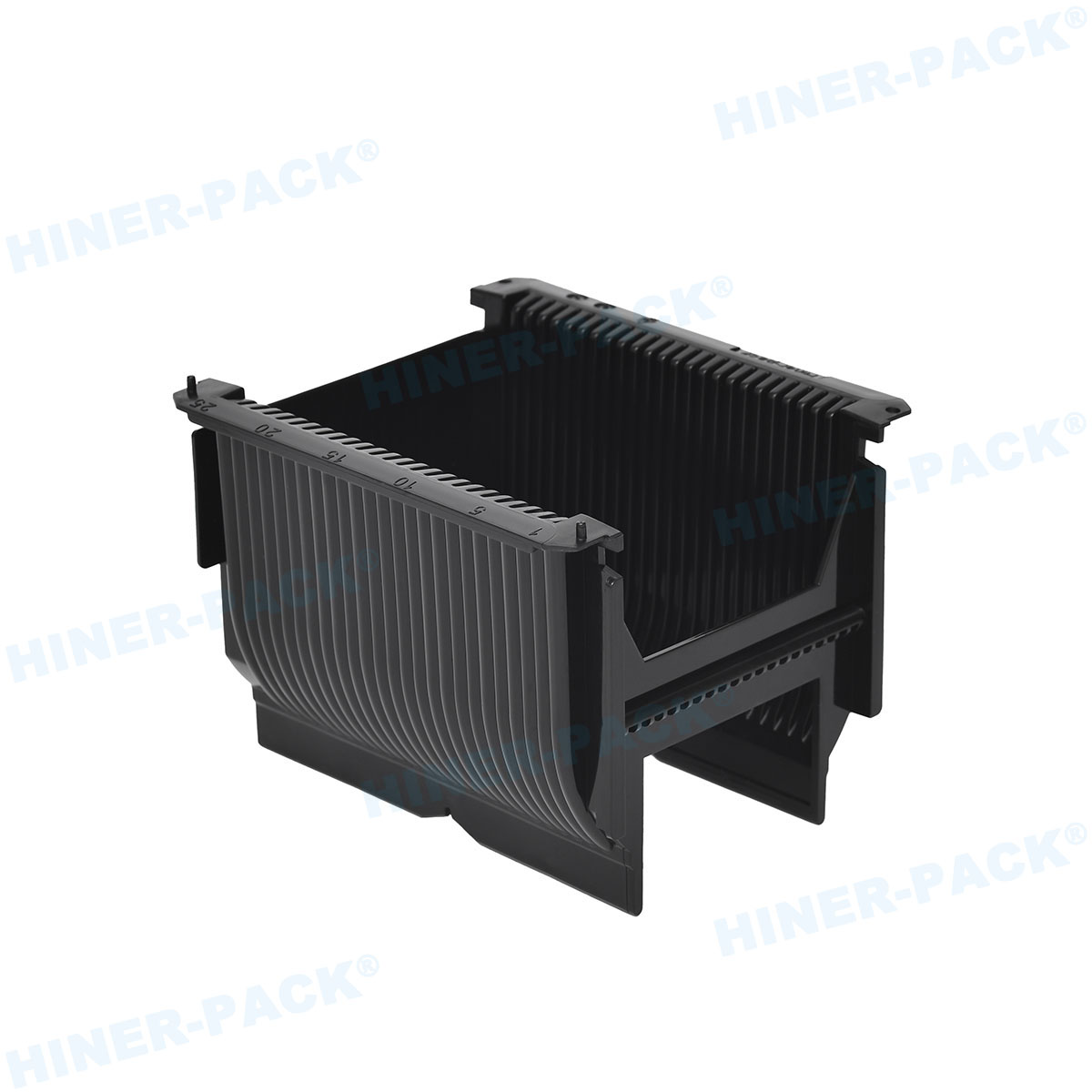

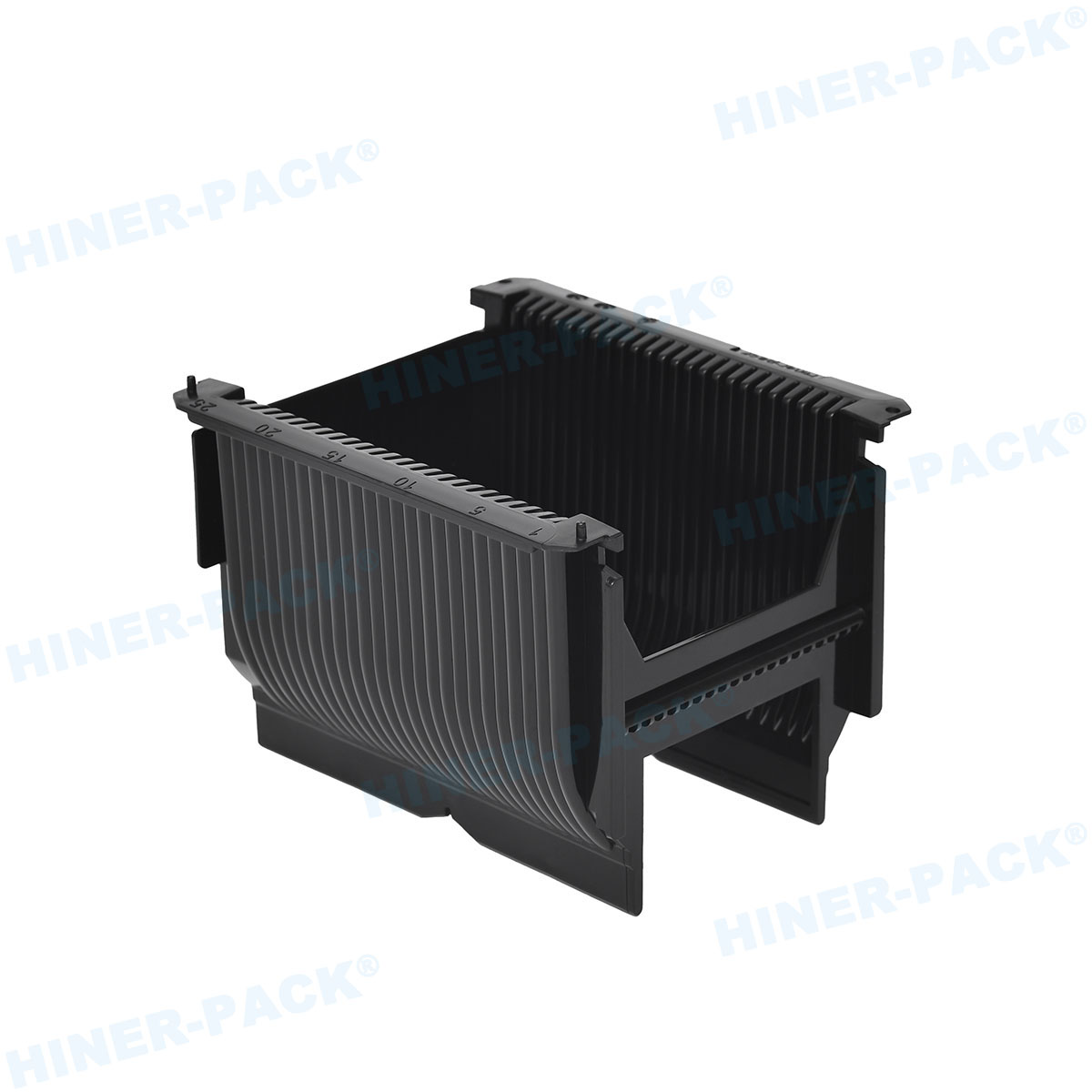

A 4 inch wafer carrier is a specialized container designed to securely hold, transport, and store silicon wafers that are 4 inches in diameter. These wafers are thin slices of semiconductor material used in the fabrication of integrated circuits, solar cells, and other microdevices. The 4 inch wafer carrier acts as a protective housing, shielding wafers from physical damage, contamination, and environmental factors like dust, moisture, and static electricity. Typically made from materials such as high-purity plastics, polycarbonate, or stainless steel, these carriers are engineered to meet stringent industry standards. They often feature slots or grooves that cradle each wafer individually, preventing contact and minimizing the risk of scratches or breakage. The 4 inch wafer carrier is a fundamental part of the supply chain in semiconductor facilities, ensuring that wafers move safely through various stages of production, from initial processing to final testing. Without a reliable 4 inch wafer carrier, the integrity of sensitive wafers could be compromised, leading to costly defects and reduced productivity.

Design and Construction of a 4 Inch Wafer Carrier

The design of a 4 inch wafer carrier focuses on precision, durability, and compatibility with automated handling systems. Most 4 inch wafer carriers are constructed from materials that offer high chemical resistance and low particulate generation, such as PFA (perfluoroalkoxy alkane) or PTFE (polytetrafluoroethylene). These materials are chosen for their ability to withstand harsh cleanroom environments and cleaning processes without degrading. A typical 4 inch wafer carrier includes features like ergonomic handles for manual handling, stacking capabilities for efficient storage, and RFID tags or barcodes for tracking purposes. The internal structure consists of precisely spaced slots that accommodate standard 4-inch wafers, often with anti-static properties to prevent electrostatic discharge, which can damage electronic components. Additionally, many 4 inch wafer carrier models are designed with ventilation holes to facilitate proper airflow during cleaning or drying cycles. The robustness of a 4 inch wafer carrier ensures it can endure repeated use in high-throughput settings, while its lightweight nature reduces operator fatigue. Innovations in design, such as modular components or custom configurations, allow the 4 inch wafer carrier to adapt to specific process requirements, making it a versatile tool in advanced manufacturing.

Applications of the 4 Inch Wafer Carrier in Industry

The 4 inch wafer carrier finds extensive use across various industries, particularly in semiconductor manufacturing, where it supports processes like lithography, etching, and doping. In these settings, the 4 inch wafer carrier enables the safe transfer of wafers between equipment, such as from a deposition chamber to an inspection station. Beyond traditional chip production, the 4 inch wafer carrier is also employed in photovoltaic cell manufacturing for solar panels, where 4-inch wafers are common due to their balance of size and efficiency. Research and development laboratories rely on the 4 inch wafer carrier for prototyping and testing new materials, as it provides a standardized means of handling small-batch wafers. Moreover, the 4 inch wafer carrier is used in medical device fabrication and MEMS (micro-electromechanical systems) production, where precision and cleanliness are paramount. In educational institutions, the 4 inch wafer carrier serves as a training tool for students learning about microfabrication techniques. The adaptability of the 4 inch wafer carrier across these domains highlights its role as a backbone in technology-driven sectors, ensuring that wafer-based products maintain high quality from conception to completion.

Advantages of Using a 4 Inch Wafer Carrier

Employing a 4 inch wafer carrier offers numerous benefits that enhance operational efficiency and product reliability. Firstly, the 4 inch wafer carrier provides superior protection against contamination and mechanical stress, which is crucial for maintaining wafer integrity in sensitive processes. This directly translates to higher yields and lower scrap rates, saving costs in high-volume production. Secondly, the 4 inch wafer carrier is designed for compatibility with automated systems, allowing seamless integration into robotic arms and conveyor belts, which speeds up throughput and reduces human error. Another advantage is the reusability and longevity of a well-maintained 4 inch wafer carrier; with proper care, it can withstand hundreds of cycles, making it an economical choice over time. Additionally, the standardized dimensions of the 4 inch wafer carrier facilitate interoperability with global equipment, simplifying logistics and supply chain management. Environmental considerations also come into play, as many 4 inch wafer carrier models are made from recyclable materials, supporting sustainability initiatives. Overall, the 4 inch wafer carrier contributes to a more streamlined, safe, and cost-effective workflow, making it an invaluable asset in any facility handling 4-inch wafers.

Maintenance and Best Practices for 4 Inch Wafer Carriers

Proper maintenance of a 4 inch wafer carrier is essential to extend its lifespan and ensure consistent performance. Regular cleaning is a cornerstone of upkeep; the 4 inch wafer carrier should be cleaned using approved solvents or deionized water in a controlled environment to remove residues and particles. Ultrasonic cleaning baths are often recommended for a thorough cleanse without damaging the carrier's structure. It's important to inspect the 4 inch wafer carrier periodically for signs of wear, such as cracks, warping, or slot damage, which could compromise wafer safety. Storage should be in a clean, dry area to prevent contamination, and stacking should follow manufacturer guidelines to avoid deformation. When handling the 4 inch wafer carrier, operators should use appropriate personal protective equipment (PPE) to minimize human-induced contaminants. Documentation and tracking via barcodes or RFID systems can help monitor usage cycles and schedule maintenance proactively. By adhering to these best practices, users can maximize the efficiency and reliability of their 4 inch wafer carrier, reducing downtime and maintaining high standards in wafer management.

Comparison with Other Wafer Carrier Sizes

While the 4 inch wafer carrier is a staple in many applications, it's helpful to compare it with carriers for other wafer sizes, such as 6-inch, 8-inch, or 12-inch variants. The 4 inch wafer carrier is often favored for its compactness and suitability for smaller-scale production or research, where larger wafers might be overkill. In terms of cost, the 4 inch wafer carrier is generally more affordable than carriers for larger wafers, making it accessible for startups or educational settings. However, larger carriers offer higher capacity per unit, which can improve throughput in mass production. The 4 inch wafer carrier also tends to be lighter and easier to handle manually, whereas larger carriers often require automated assistance. Despite these differences, the fundamental design principles—such as material choice and protective features—remain similar across sizes. The 4 inch wafer carrier continues to hold relevance in niches where its size aligns with specific technological requirements, such as in legacy systems or specialized devices.

Future Trends in 4 Inch Wafer Carrier Technology

The evolution of the 4 inch wafer carrier is influenced by advancements in materials science and automation. Future iterations may incorporate smart features, such as embedded sensors for real-time monitoring of temperature, humidity, or shock, enhancing the traceability and safety of wafers. Sustainable materials are another area of focus, with research into bio-based plastics or enhanced recyclability for the 4 inch wafer carrier to reduce environmental impact. As industries move toward greater miniaturization and precision, the 4 inch wafer carrier might see improvements in slot accuracy and anti-static properties to handle thinner, more fragile wafers. Collaboration with IoT (Internet of Things) platforms could enable the 4 inch wafer carrier to integrate with digital twin systems, providing data analytics for predictive maintenance. These innovations will ensure that the 4 inch wafer carrier remains a critical component in the ever-evolving landscape of semiconductor and electronics manufacturing.

In summary, the 4 inch wafer carrier is more than just a container; it's a precision tool that safeguards one of the most valuable components in technology production. From its robust design to its wide-ranging applications, the 4 inch wafer carrier plays a pivotal role in ensuring quality and efficiency. By understanding its features and adhering to best practices, businesses can leverage the full potential of the 4 inch wafer carrier to drive innovation and success.

Frequently Asked Questions about 4 Inch Wafer Carriers

Q1: What materials are commonly used in a 4 inch wafer carrier?

A1: A 4 inch wafer carrier is typically made from high-purity plastics like PFA or PTFE, which offer excellent chemical resistance and low particulate generation. Some models may use polycarbonate or stainless steel for added durability in specific environments.

Q2: How does a 4 inch wafer carrier prevent wafer damage?

A2: The 4 inch wafer carrier prevents damage through features like individually spaced slots that minimize wafer-to-wafer contact, anti-static properties to avoid electrostatic discharge, and robust construction that shields wafers from physical shocks and contaminants.

Q3: Can a 4 inch wafer carrier be used in automated systems?

A3: Yes, most 4 inch wafer carriers are designed for compatibility with automated handling equipment, such as robotic arms and conveyor systems, ensuring smooth integration into high-throughput manufacturing processes.

Q4: How often should a 4 inch wafer carrier be cleaned?

A4: It's recommended to clean a 4 inch wafer carrier after each use or based on the contamination level of your process. Regular inspections and cleaning cycles help maintain performance and extend the carrier's lifespan.

Q5: Are there industry standards for 4 inch wafer carriers?

A5: Yes, the 4 inch wafer carrier often adheres to standards set by organizations like SEMI (Semiconductor Equipment and Materials International), which specify dimensions, materials, and performance criteria to ensure interoperability and quality.