In the highly precise world of semiconductor manufacturing, every component plays a vital role in ensuring efficiency, yield, and cost-effectiveness. One such essential element is the 300mm wafer cassette, a specialized container designed to handle and protect large silicon wafers during various stages of production. As the industry shifts toward larger wafer sizes to boost productivity, understanding the 300mm wafer cassette becomes crucial for professionals and enthusiasts alike. This article delves into the key aspects of the 300mm wafer cassette, highlighting its importance, design, and applications. By exploring its multifaceted role, we can appreciate why this component is indispensable in modern electronics. Whether you're involved in fabrication, research, or simply curious about semiconductor technology, this overview will provide valuable insights into how the 300mm wafer cassette supports the creation of the devices we use daily.

What Is a 300mm Wafer Cassette?

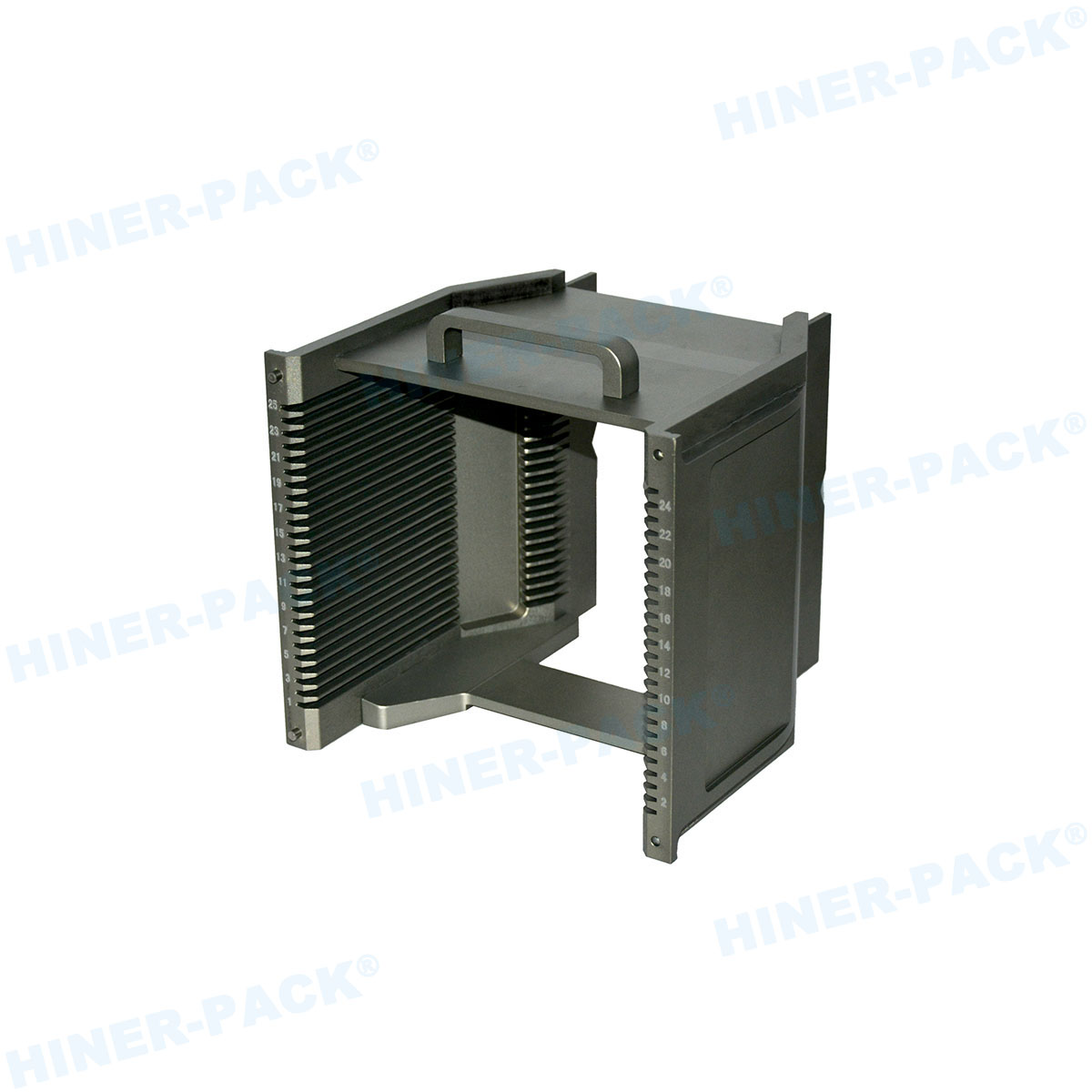

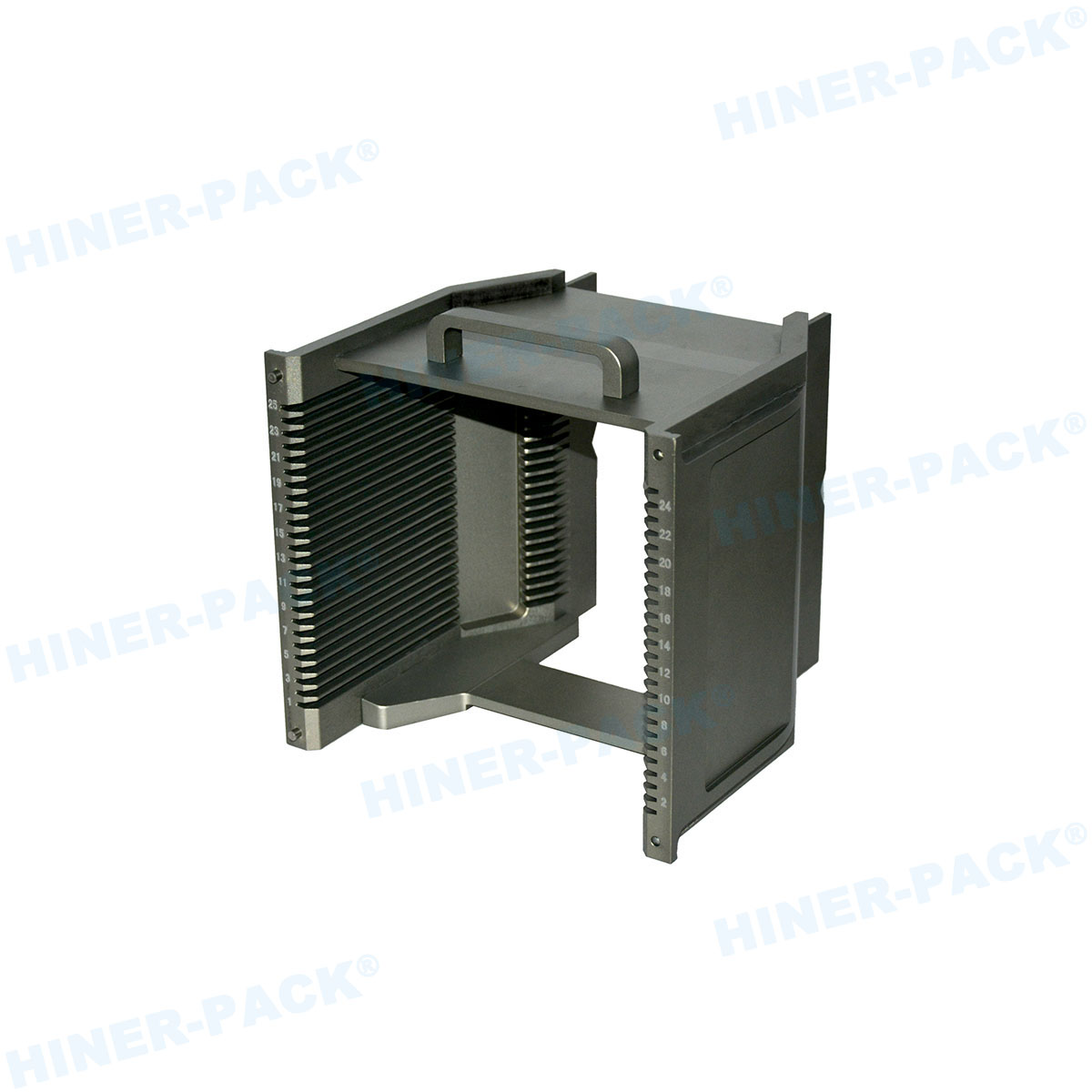

A 300mm wafer cassette is a standardized carrier used in the semiconductor industry to store, transport, and protect silicon wafers that are 300 millimeters in diameter. These cassettes, often made from high-purity materials like plastics or composites, are engineered to minimize contamination and physical damage to the wafers. They typically feature slots that hold wafers securely in place, allowing for automated handling in cleanroom environments. The adoption of the 300mm wafer cassette coincided with the industry's move toward larger wafers, which began in the early 2000s to increase the number of chips produced per wafer, thereby reducing costs. This cassette is a key part of the Front Opening Unified Pod (FOUP) system, which encloses wafers in a controlled atmosphere to prevent exposure to particles, moisture, or other contaminants. Essentially, the 300mm wafer cassette acts as a protective shell that ensures wafers remain pristine from fabrication to assembly, supporting the high yields required in today's competitive market.

The design of the 300mm wafer cassette is not arbitrary; it follows strict industry standards set by organizations like SEMI (Semiconductor Equipment and Materials International). These standards ensure compatibility across different manufacturing tools and facilities, facilitating seamless integration into production lines. Each 300mm wafer cassette can typically hold up to 25 wafers, though this can vary based on specific designs. The cassette's structure includes features like handles for manual or robotic handling, alignment guides for precise positioning, and ventilation to manage internal environments. By providing a controlled interface between wafers and processing equipment, the 300mm wafer cassette helps maintain the integrity of delicate semiconductor materials, which is essential for producing high-performance integrated circuits. As wafer sizes continue to influence manufacturing efficiency, the role of the 300mm wafer cassette remains central to advancing semiconductor technology.

Design and Construction of the 300mm Wafer Cassette

The design of the 300mm wafer cassette is a marvel of engineering, focused on precision, durability, and contamination control. Typically constructed from materials such as polycarbonate, PEEK (polyether ether ketone), or other high-performance plastics, these cassettes are chosen for their low particle generation and resistance to chemicals used in semiconductor processes. The cassette body includes multiple slots spaced precisely to accommodate the 300mm wafers without causing stress or contact that could lead to defects. Each slot is often lined with soft, non-abrasive materials to cushion the wafers and prevent scratches during insertion and removal. Additionally, the 300mm wafer cassette features a front-opening mechanism that aligns with standardized load ports on processing equipment, enabling automated handling by robotics. This automation is critical for maintaining high throughput in fabs (fabrication plants), where human intervention is minimized to reduce contamination risks.

Another key aspect of the 300mm wafer cassette design is its integration with environmental controls. Many cassettes are part of a sealed system, such as the FOUP, which includes filters and purge capabilities to maintain a clean, inert atmosphere inside. This is vital for protecting wafers from airborne particles, humidity, and static electricity, which can ruin sensitive circuit patterns. The cassette may also include RFID tags or barcodes for tracking purposes, allowing manufacturers to monitor wafer lots throughout the production cycle. The robust construction of the 300mm wafer cassette ensures it can withstand repeated use in harsh conditions, including exposure to high temperatures, chemicals, and mechanical stress. By adhering to stringent design standards, the 300mm wafer cassette supports the scalability and reliability of semiconductor manufacturing, making it a cornerstone of modern chip production.

Functions and Applications in Semiconductor Fabrication

The primary function of the 300mm wafer cassette is to serve as a protective carrier for silicon wafers during the various stages of semiconductor fabrication. In a typical fab, wafers undergo numerous processes, including lithography, etching, doping, and deposition, each requiring precise handling and isolation from contaminants. The 300mm wafer cassette enables this by providing a standardized interface that allows wafers to be transferred between different tools without direct human contact. This reduces the risk of defects, such as particles adhering to the wafer surface, which can lead to yield losses. Moreover, the cassette's design supports high-volume production by facilitating rapid loading and unloading through automated systems. This efficiency is crucial for meeting the demands of industries like computing, automotive, and consumer electronics, where semiconductor components are in constant demand.

In applications beyond basic transport, the 300mm wafer cassette plays a role in storage and inventory management. Wafers may be stored in these cassettes for extended periods in controlled environments, such as cleanrooms or nitrogen-purged cabinets, to preserve their quality. The cassette's compatibility with stockers and automated material handling systems (AMHS) allows for efficient warehouse management and just-in-time delivery to production lines. Additionally, the 300mm wafer cassette is integral to testing and metrology phases, where wafers are inspected for defects or electrical properties. By ensuring that wafers remain aligned and uncontaminated, the cassette helps maintain the accuracy of these measurements. Overall, the 300mm wafer cassette is a versatile tool that underpins the entire semiconductor manufacturing workflow, from raw wafer intake to final packaging, highlighting its indispensable nature in achieving high yields and operational excellence.

Materials and Durability Considerations

The materials used in manufacturing a 300mm wafer cassette are selected based on their ability to withstand the rigorous conditions of semiconductor fabs while minimizing contamination. Common materials include advanced polymers like polycarbonate, which offers good mechanical strength and transparency for visual inspection, and PEEK, known for its high thermal stability and chemical resistance. These materials are often treated with anti-static coatings to prevent electrostatic discharge (ESD), which can damage sensitive wafers. The durability of a 300mm wafer cassette is critical because it undergoes frequent cycling between equipment, exposure to cleaning agents, and potential impacts during handling. Manufacturers subject these cassettes to extensive testing, including cycle life tests that simulate years of use to ensure they maintain structural integrity and performance.

Beyond material choice, the design of the 300mm wafer cassette incorporates features to enhance longevity, such as reinforced edges and wear-resistant slots. Regular maintenance, including cleaning and inspection, is essential to prevent the buildup of contaminants that could compromise wafer quality. The cassette's ability to resist deformation under load and temperature variations is also a key factor, as semiconductor processes often involve extreme conditions. For instance, during thermal processing, the 300mm wafer cassette must not outgas or release particles that could contaminate the wafers. By focusing on material science and robust engineering, the 300mm wafer cassette achieves a balance between lightweight handling and long-term reliability, supporting the industry's push toward more sustainable and cost-effective manufacturing practices.

Cleaning and Maintenance Protocols

Proper cleaning and maintenance of the 300mm wafer cassette are vital to prevent contamination and ensure consistent performance in semiconductor production. Cleaning protocols typically involve automated or manual processes using ultra-pure water, solvents, or specialized detergents that remove particles, residues, and static charges without damaging the cassette. In many fabs, cassettes are cleaned in dedicated equipment that follows strict cycles, including rinsing, drying, and inspection for defects. The frequency of cleaning depends on usage; for example, a 300mm wafer cassette used in high-particulate environments may require daily cleaning, while others might be serviced weekly. Maintenance also includes checking for physical wear, such as cracks or slot deformities, which could misalign wafers and cause breakage.

In addition to routine cleaning, the 300mm wafer cassette may undergo preventive maintenance to replace worn components, such as seals or liners, to extend its lifespan. Documentation and tracking are often part of this process, using the cassette's identification features to log cleaning history and performance metrics. This proactive approach helps minimize downtime and reduce the risk of cross-contamination between wafer lots. Furthermore, as industry standards evolve, cleaning methods for the 300mm wafer cassette are continuously refined to address new challenges, such as nanoscale particles or chemical compatibility with advanced materials. By adhering to rigorous maintenance schedules, manufacturers can maximize the utility of each 300mm wafer cassette, contributing to higher yields and lower operational costs in semiconductor fabrication.

Advantages and Industry Impact

The adoption of the 300mm wafer cassette has brought significant advantages to the semiconductor industry, primarily through improved efficiency, cost savings, and enhanced yield rates. By enabling the handling of larger 300mm wafers, these cassettes allow fabs to produce more chips per wafer compared to smaller sizes like 200mm, reducing the cost per die. This scalability is essential for keeping pace with the growing demand for electronics. The standardized design of the 300mm wafer cassette also promotes interoperability across global supply chains, facilitating collaboration and technology transfer. Moreover, the cassette's role in automation reduces labor costs and human error, leading to faster production cycles and higher quality outputs.

From an environmental perspective, the 300mm wafer cassette supports sustainability efforts by minimizing material waste and energy use through optimized processes. For instance, the sealed systems associated with these cassettes reduce the need for frequent cleanroom air changes, lowering energy consumption. The industry impact extends to innovation, as the reliability of the 300mm wafer cassette enables the development of more complex semiconductor devices, such as those used in AI, 5G, and IoT applications. As manufacturers push the limits of Moore's Law, the 300mm wafer cassette remains a foundational element that drives progress. Its continued evolution, including potential integration with smart manufacturing technologies, ensures that it will play a key role in the future of electronics, making it a topic of ongoing interest and investment.

Frequently Asked Questions

Q1: What is the primary purpose of a 300mm wafer cassette?

A1: The primary purpose of a 300mm wafer cassette is to safely store, transport, and protect silicon wafers during semiconductor manufacturing processes. It helps prevent contamination, physical damage, and misalignment, ensuring high yields and efficiency in production.

Q2: How many wafers can a standard 300mm wafer cassette hold?

A2: A standard 300mm wafer cassette typically holds up to 25 wafers, though this can vary based on design and manufacturer specifications. The slots are precisely spaced to accommodate the wafers without contact.

Q3: What materials are commonly used in making a 300mm wafer cassette?

A3: Common materials for a 300mm wafer cassette include high-purity plastics like polycarbonate and PEEK, which offer durability, chemical resistance, and low particle generation. These materials are often coated to reduce static and contamination.

Q4: How often should a 300mm wafer cassette be cleaned?

A4: The cleaning frequency for a 300mm wafer cassette depends on usage and environmental factors, but it is generally recommended after each use or according to a regular schedule—such as daily or weekly—in high-volume fabs to maintain cleanliness.

Q5: Can a 300mm wafer cassette be used with automated systems?

A5: Yes, the 300mm wafer cassette is designed for compatibility with automated handling systems, including robotics and AMHS. Its standardized front-opening interface allows for seamless integration into modern semiconductor fabrication lines.