In the high-stakes world of semiconductor manufacturing, where a single silicon wafer can be worth tens of thousands of dollars, its safe passage from one fabrication step to another—or across the globe—is non-negotiable. This is where the single wafer shipper transitions from a simple box to a mission-critical piece of equipment. It is the first and last line of defense for the heart of the electronics industry. For companies like Hiner-pack, engineering these containers is not just about logistics; it's about preserving billions of dollars in R&D and production value.

This article delves into the multifaceted role of the modern single wafer shipper, exploring its design, the critical requirements it must meet, and why choosing the right partner is a strategic business decision.

The Evolution from Bulk to Single Wafer Protection

The semiconductor industry's journey has been marked by increasing wafer sizes and decreasing node sizes. Older, bulk carriers that held multiple wafers in a cassette within a box posed significant risks: particulate generation from wafer-to-wafer contact, cross-contamination, and catastrophic loss during transit if the carrier was compromised. The move towards the single wafer shipper was a direct response to these vulnerabilities.

This evolution was driven by several factors:

Larger Wafer Sizes: As the industry moved to 300mm and now 450mm wafers, the value and surface area per wafer increased exponentially, making individual protection paramount.

Advanced Node Sensitivities: At 5nm, 3nm, and beyond, wafers are incredibly sensitive to minute particles and airborne molecular contamination (AMC). A traditional carrier simply cannot provide the requisite level of cleanliness.

Supply Chain Globalization: Wafers often travel between specialized foundries, packaging houses, and end-users across different continents, demanding robust, secure, and standardized transport solutions.

The single wafer container has become the undisputed standard for protecting high-value wafers during this complex journey.

Deconstructing the Design: More Than Just a Box

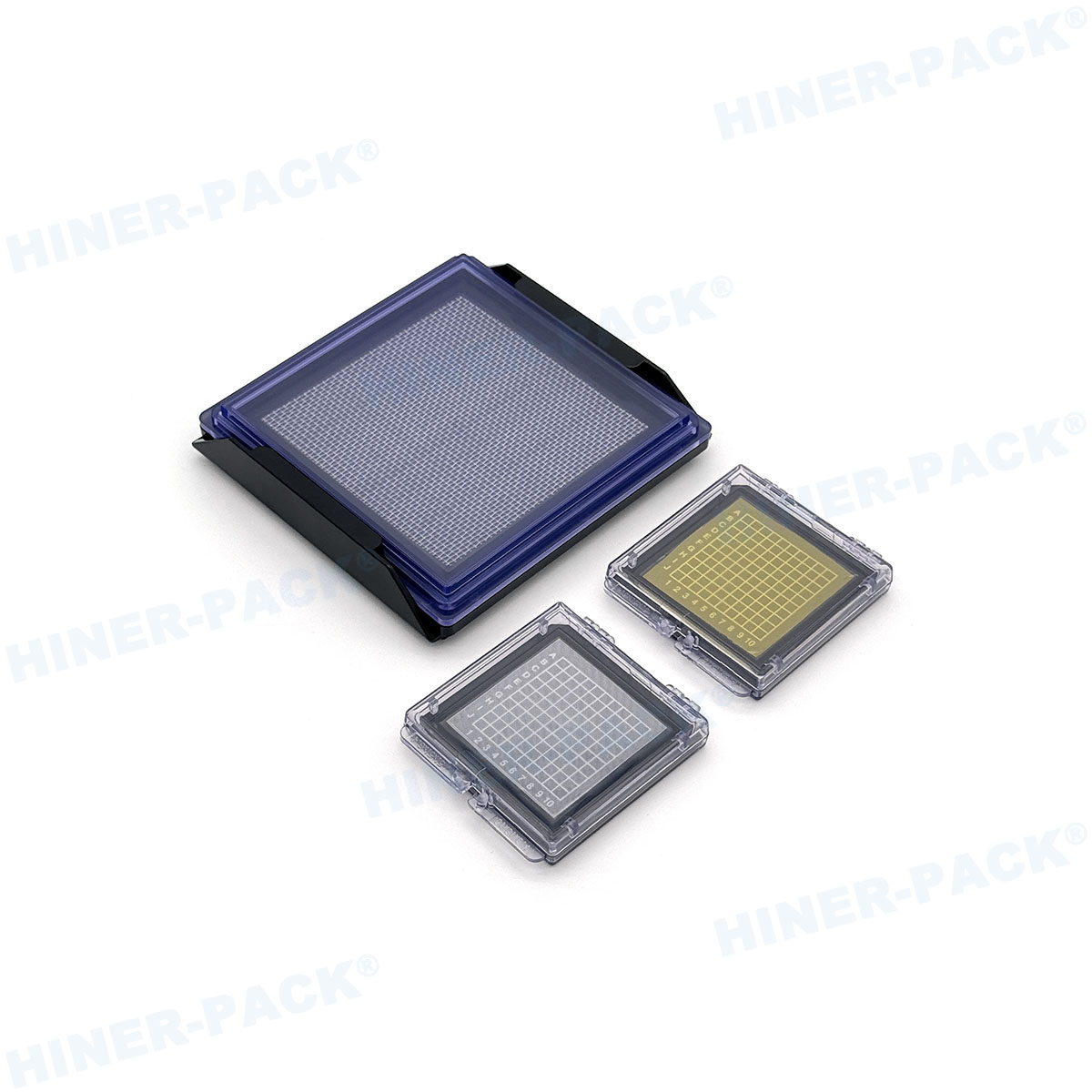

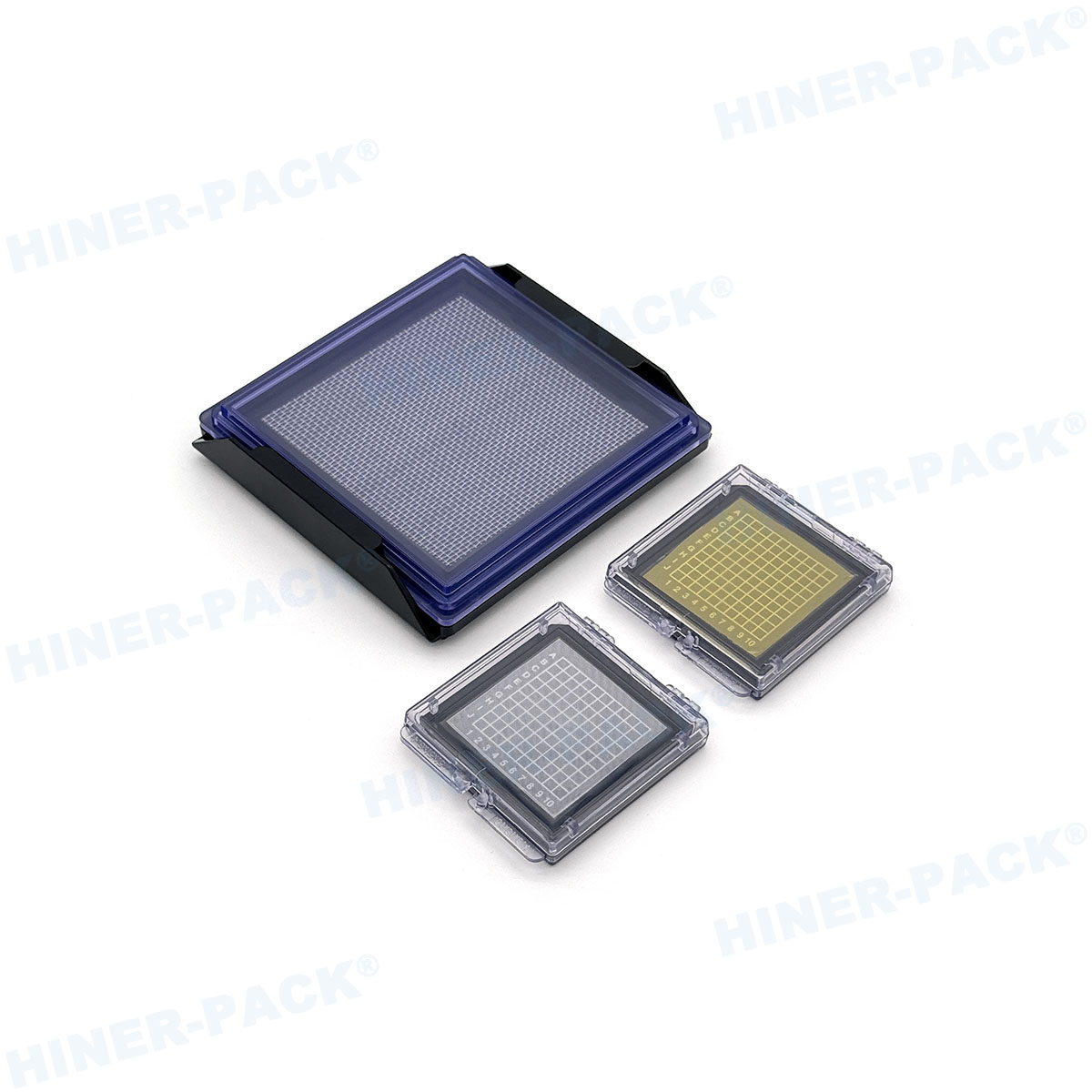

A high-quality single wafer shipper is a marvel of engineering precision. It is a fully integrated system designed to create a stable, pristine micro-environment. Key components include:

Rigid Outer Shell: Typically made from advanced, static-dissipative polymers, the shell must withstand physical shocks, compression forces during stacking, and environmental extremes encountered in air cargo holds.

Cushioning and Retention System: This is the core of the protection. Custom-molded foam or polymeric fixtures gently but securely hold the wafer by its edges, preventing any movement (G-level shock and vibration isolation) and ensuring no contact with the sensitive device patterns. Companies like Hiner-pack use finite element analysis to design cushioning that absorbs specific shock frequencies.

Contamination Control: The interior is a cleanroom-in-a-box. Materials are selected for low outgassing and minimal particle shedding. Seals are designed to be highly effective, often meeting or exceeding SEMI standards for preventing the ingress of particles and AMC.

RFID and Traceability: Modern single wafer shipper designs incorporate dedicated slots for RFID tags and barcodes. This allows for seamless tracking of the wafer's journey through the supply chain, a critical feature for logistics management and quality control.

Key Performance Metrics for a Superior Single Wafer Container

When evaluating a single wafer shipper, manufacturers focus on several non-negotiable performance metrics:

Mechanical Shock and Vibration Dampening: The container must protect against drops and the constant vibrations of transport. Certified testing ensures the wafer experiences forces well below its fracture threshold.

Thermal Stability: Materials must not warp, degrade, or outgas excessively across a wide temperature range, from the cold of an airplane cargo hold to the warmth of a loading dock.

ESD Protection: Static charge can destroy delicate circuits on a wafer. The entire single wafer container must be constructed from materials that safely dissipate electrostatic discharge.

Cleanliness Compliance: Adherence to international standards like SEMI E158 is crucial. This certifies that the container itself will not become a source of contamination.

Hiner-pack's products are rigorously tested against these metrics, ensuring they meet the stringent demands of leading-edge fabs.

The Economic Impact: Cost Savings of a Reliable Wafer Shipper

While a premium single wafer shipper has an upfront cost, its return on investment is substantial. The cost of a single wafer loss or yield degradation due to transport damage far outweighs the investment in robust packaging. The economic benefits include:

Dramatically Reduced Yield Loss: Preventing physical damage, contamination, and ESD events directly preserves yield.

Lower Total Cost of Ownership (TCO): Durable, reusable single wafer shipper designs from Hiner-pack can withstand multiple trips, reducing per-shipment costs compared to single-use alternatives.

Supply Chain Efficiency: Standardized, stackable designs optimize shipping volume and simplify handling, saving on freight and labor costs.

Hiner-pack's Approach to Advanced Wafer Shipping Solutions

At Hiner-pack, we understand that a single wafer shipper is a critical link in your value chain. Our philosophy is built on three pillars:

Collaborative Engineering: We work directly with customers to understand their specific process and logistics challenges, tailoring solutions for unique wafer types or extreme travel conditions.

Material Science Expertise: We invest in research on next-generation polymers and composites to create lighter, stronger, and cleaner containers.

Quality as a Standard: Every Hiner-pack single wafer container is manufactured in a controlled environment and undergoes a stringent quality assurance process, providing the reliability our global clients depend on.

By focusing on these areas, Hiner-pack ensures that our single wafer shipper products are not just containers, but enablers of a more efficient and secure semiconductor ecosystem.

Frequently Asked Questions (FAQs) About Single Wafer Shippers

Q1: What is the main advantage of a single wafer shipper over a traditional multi-wafer cassette carrier?

A1: The primary advantage is the drastic reduction of risk. A single wafer shipper eliminates wafer-to-wafer contact, preventing cross-contamination and physical damage. It provides a dedicated, sealed environment for each high-value wafer, which is essential for large 300mm/450mm wafers and advanced process nodes where even a single particle can cause significant yield loss.

Q2: Are single wafer shippers reusable, and how do I ensure they are clean for reuse?

A2: Many high-quality single wafer shipper models, like those from Hiner-pack, are designed for multiple uses. Reusability is a key factor in reducing the total cost of ownership. For reuse, they must be processed through a certified wafer carrier cleaning procedure to remove particles and molecular contaminants. Always follow the manufacturer's cleaning guidelines and validate cleanliness before each new use.

Q3: How does a single wafer container protect against electrostatic discharge (ESD)?

A3: A reliable single wafer container is constructed from static-dissipative or conductive materials. These materials prevent the buildup of static electricity by allowing any charge to flow safely across the surface and dissipate harmlessly, rather than discharging through the sensitive wafer. Hiner-pack designs its containers to meet strict ESD safety standards.

Q4: What industry standards should a compliant single wafer shipper meet?

A4: Key international standards include SEMI E158 for mechanical specification and environmental requirements for 300mm single wafer shippers, and SEMI E163 for 450mm models. Compliance with these standards ensures interoperability, mechanical robustness, and cleanliness. Reputable suppliers will have their products tested and certified to these benchmarks.

Q5: Can single wafer shippers be customized for specific wafer types or logistical needs?

A5: Absolutely. While standard models exist, many suppliers, including Hiner-pack, offer customization. This can include tailored cushioning for ultra-thin wafers, specific RFID tag integration, custom branding or color-coding for easy identification, and modifications to support specialized automation handling equipment in the fab.